Supply Chain and Logistics Management, Uncategorized

Transform Production Control by Authentically Managed Bills of Material Data in Dynamics 365

Transform Production Control by Managed Bills of Materials (BOM)

Bills of Materials | Production Control | Dynamics 365

Whether a start-up or a multi-national enterprise, almost all scale organizations go through production control in one way or another.

As we all know, production control is basically a production plan and various techniques to ensure that plan is working correctly. It comprises of establishing the optimal route for every item, assembly of the product; that includes materials, labor and machinery, finishing dates of essential items, releasing of crucial orders, and a quick follow up for inventory tracking and effectuate the smooth running of the company.

Now, it’s not easy to manage all of these things, especially when dealing with numerous ongoing projects, and the production control isn’t immune to issues or errors; either it is AI or HI. Microsoft’s Dynamics AX, as always, acts as our ally and saves the day with its numerous tools and integrations.

Further, in today’s post, we will elaborate on issues during the production processes and how you can reduce them and transform the process using Dynamics 365, especially by managing bills of materials data.

So, let’s start from scratch and see why production control isn’t immune to the errors and what those errors are actually.

The introduction of this post explains how industrial production control requires correct and accurate planning for the continuous running of product lifecycle management. Different components such as machinery, labor, route, and orders release play a decisive role in the inefficient running of the enterprise.

What Issues Could Occur in Production Process?

Production control is an important component of operations and case management. Nonetheless, carrying it out in a simple way won’t give your company the perfection you might be looking for. After all, several things can cause errors and sabotage the smooth running of the enterprise. Even minute errors can cause distortions and damage production and profitability.

When you step into the growth period of the production cycle, you need to start focusing on reducing flaws. So, here are four components where the errors could be most evident.

Processing Errors

As the name suggests, this sort of flaw occurs when an individual or a group of individuals do not follow the standard operating procedures. However, companies can also face such obstacles when they don’t establish any standard procedures in the first place.

Adequate standards are vital when you are up to error reduction and rapid growth. Several companies end up dealing with massive errors just because they are missing out on standard operations for production and performance. Once a company establishes standard processes, it also needs to address all the workers to know the importance of procedures and commit to them.

Incorrect cost of the product

Correct and organized master data holds an important position in managing operations. When you don’t get the details right, there is no way you get the outcome right. To get the exact cost of the product, Dynamics 365 offers costing BOM. It is essentially a list of raw materials or any component that makes up an item.

Adding relevant details in BOM industries can get the total cost of the item and make their operation run smoothly and error-free. If your curiosity isn’t restraining you from knowing the process of adding BOM, you scroll down to the fourth heading and get to the steps where we explain how you can manage your bills of materials example data in Dynamics 365.

Portion Errors

When an incorrect measurement produces a machine malfunction or a production slowdown, errors can occur in the manufacturing process. Employees can utilize signs and checklists to identify what portion sizes should be used in various equipment throughout the production line.

Signs in the workplace may be a simple way to raise knowledge of proper equipment use. They should include essential messages that will assist team members in remaining focused and completing the work at hand without inserting the incorrect component or quantity of a part in a piece of equipment.

People Errors

People’s mistakes are typically the least expected and the costliest. Companies can reduce human errors with adequate training and clear protocols, but no organization can completely eliminate individual mistakes. You may learn from these human blunders and create more robust systems to prevent future failures.

|

Sr. |

Production Control KPIs to Track Operational Excellence | ||

| KPI | Description | Accuracy | |

|

1. |

On-Time Delivery

(Work Orders Delivered by the Original Schedule Date ÷ Original Schedule Work Orders Due) |

This KPI measures the percentage of orders delivered on-time | The metric is often tallied monthly for statistical relevance and the aim should be 100% fulfillment |

|

2. |

Production Schedule Attainment

(Work Orders Delivered by the Original Schedule Date ÷ Original Schedule Work Orders Complete) |

Tracks how often the production team achieves the desired level of output, which is useful for setting performance standards, fine-tuning work order delivery time estimates, and ensuring that performance problems don’t cause expensive delays | Ensuring on-time delivery |

|

3. |

Throughput

(Units Produced / Time) |

This is the rate of how many units on average a machine, cell or line is producing over time | Less throughput is a problem, the greater the throughput, the better it is |

|

4. |

Capacity Utilization

(Actual Output / Potential Output x 100) |

Measure of the facility’s ability to scale production or institute more agile job scheduling during production time | Less idle time, the better will be utilization |

|

5. |

Yield

Good Parts

(Produced / Total Units Produced) |

Measure of quality and performance and is at the heart of production efficiency and profitability | Target of a 100% yield |

|

6. |

OEE – Overall Equipment Effectiveness

(Availability * Performance * Quality)

|

OEE acts as a safeguard for production | The greater the OEE, the greater is the level of manufacturing excellence |

SUMMARY

The more production capacity a company holds, the more it is prone to fatal errors that could bring delays and profit loss or even cause bad reputation. Above is the list of the four most commonly occurring errors during the production process. All of these errors come with a solution explained with each one of the issues. Errors such as process and people are usually the last ones to expect, but they cost a great deal in terms of both time and money when they occur.

How to Overcome Production Errors?

Error elimination is one of a company’s primary concerns if it wishes to meet its quality goals. This logic encompasses the installation of relevant instruments. To provide and maintain actual efficiency, the organization must be really tailored to the needs of the firm. Correct implementations can operate properly for any systems that are compatible with others.

All human and material components that might impact the quality of production and customer satisfaction are included in the mistake elimination process. It necessitates the active participation of agile employees’ supervisors, and an aggressive attitude and leadership.

This system will not be helpful until it is linked to system approach management and process, and factual systematic methods to better decision-making. Concentrating on the consumer and ensuring that mutually beneficial supplier connections complete the list of factors influencing the item’s success.

Perform upstream to prevent error occurrence

If there isn’t a totally dependable (robust) continuous procedure in place to prevent errors, they will almost certainly occur at some point.

By specifying a criticality order, FMECA (Failure Modes, Effects, and Criticality Analysis) must be used to prioritize continuous improvement operations (product of the probability of occurrence of an accident by the severity of its effects). It entails identifying the mistakes that are likely to occur at any step of production and defining preventative actions to avoid them through a collaborative brainstorming process in which all departments of the organization participate.

Ensure Product Quality

This technique, which is based on collaboration, suggests the production of seven-step fact sheets to address the fundamental causes of errors:

- Establish a working group.

- Describe the situation.

- Identify the quick remedial measures that need to be taken.

- Discover the true sources of the issue, select the appropriate remedies.

- Corrective steps should be implemented and validated.

- Decide on the preventative measures.

You can read another quality check method that we discussed in detail in our previous blog, “How to perform a root cause analysis of late shipments in D365“. On this blog, you will find an in-detail discussion on using the Ishikawa diagram to find out the cause giving rise to the error.

The Ishikawa diagram is based on five M’s, i.e., the material, the method, the labor, and the environment. In the end, you get the most direct assessable causes closer to the center.

Incorporate Better Maintenance

It is not easy to secure and achieve ongoing output without powerful machines like Dynamics 365. Maintenance operations are critical in this regard. To keep the enterprise running, it’s no longer enough to strive to prevent defects, inefficiencies and failures. The objective is also to increase performance. Total Productive Maintenance (TPM), an approach characterized by higher participation of responsible operators, is based on this idea.

Productive maintenance improves the inventory closing of production tools by utilizing the operator’s initiative and analysis.

If an analyst notices a flaw in the production, he understands how to correct it or can help discover a solution using tools and procedures. Further, an analyst can also address to flaw with the help of seniors. In the end, productive maintenance encourages this type of experience feedback since it improves the organization as a whole.

SUMMARY

Companies have been facing errors since the evolution of industrialization. While we, as humans, have the capability to breach through every problem and figure out a solution for each one of them. The above chapter of our blog explains through a number of measures and precautions through which companies can either minimize or even restrain some of the common errors for the sake of better performance and quality assurance.

How can Bills of Materials Data Help Reduce Errors?

Bills of material can help users streamline their item details by helping them to ensure several production control components. Here are some of the prominent benefits of managing your bills of materials template in Dynamics 365.

- With managed bills of material, process manufacturers can change components/ingredients (through BOM formulas), routes, co-products, and by-products.

- Managed Bills of Materials (BOM) can help the user manage product changes using work templates and can control the product lifecycle.

- BOM brings assembly and discipline to the product information management

- BOM Gives you increased data quality and reliability, allowing smoother changes, and provides reduced market time.

Change Requests and Change Orders are used to handle changes to what is bills of materials or Formulas. System users can submit change requests that are linked to sales orders, sales invoice, and purchase orders. Users can add more information to the change request by attaching files, making notes, associating goods, and linking the change request’s source (sales order, purchase order, etc.).

SUMMARY

Bills of materials, among many other helping tools, offer users to add up all the details any item could possess. Further, after adding up the component of which an item comes into production, the user can experience a disciplined production flow and even restrain some people’s errors by filtering out items with the help of their details added in bills of materials (BOM)

HOW DO YOU CREATE WORK TEMPLATES IN D365 SUPPLY CHAIN MANAGEMENT?

Engineering BOM is a list of items that specifies the components of a manufactured item (finished or semi-finished product).

In Dynamics 365, a manufactured item’s components (or material resources, parts) are not directly assigned to the product but to the bill of materials. This Bill of materials is then separately assigned to the manufactured item.

BOM Version:

The assignment of a BOM to a manufactured item is called the “BOM version” in D365. You can assign one or more BOMs to a manufactured item.

Setting up BOM:

To set up a BOM, we first need the production dimensions (that will make up the BOM) and the finished product (to which we will assign BOM). So, let’s create components and finished products.

Create Components:

Step 1

Go to Dynamics 365 Finance and Operations dashboard and change the company to USMF.

Step 2

Go to Product information management> Products> Released products and click on New.

Step 3

Enter the fields: Product number, Product Name, Search name, Item model group, Item group, Storage dimension group, Tracking dimension group, Item sales tax group, Vendor, Purchase and Inventory price and click Ok.

Step 4

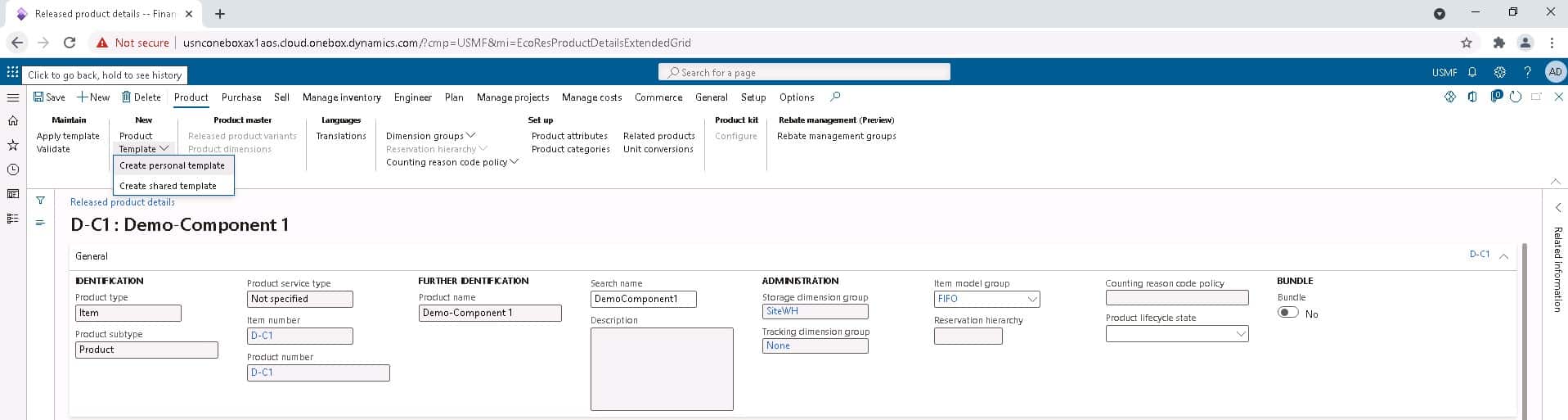

Click on tab PRODUCT/New/Template/Create personal template.

Step 5

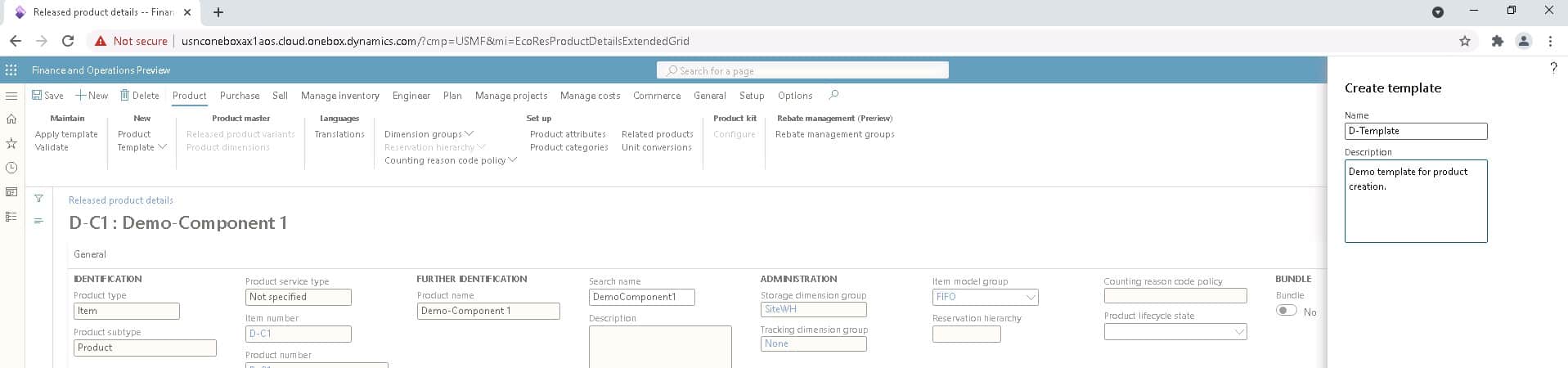

Enter the name of template and click Ok. After that close the product information form.

Step 6

On the Released product form, click on new to create the second component for BOM.

Step 7

Enter the product number, product name and in the Apply template field, select the template we created in step 5. Then click Ok and close the form.

Create Finished Product:

Finished or Manufactured product is the end result of our production process, through this we get the item we intended to make for sales.

Step 8

Go to Product information management> Products> Released products and click on New.

Step 9

Enter the necessary information about the product as shown below and click Ok.

Step 10

Go to tab Engineer and in the lookup field Production type select BOM.

Step 11

In the action pane go to MANAGE INVENTORY/Order settings/Default order settings and in the lookup field Default order type, select Production and click on Save.

Create BOM:

Step 12

Go to Product information management> Products> Released products and select the product that we created in step 9.

Step 13

Go to ENGINEER/BOM/BOM versions in the action pane.

Step 14

Click on New/BOM and BOM version in the action pane.

Step 15

Enter the BOM number and name and specify the site, then click Ok.

Step 16

Now to add the components in the BOM, click on New on the Bill of materials lines tab.

Step 17

Enter the item number and quantity and click on Save. Quantity specifies how many units of a specific component you need to create Final Product.

Step 18

Click the button BOM VERSION/Maintain BOM version/Approval in the action pane of this form to approve the BOM version.

Step 19

Select the responsible person who will approve the BOM and click Ok.

Step 20

Now click the button BOM VERSION/Maintain BOM version/Activate in the BOM version form to activate the BOM version.

The slider Active on the tab BOM version then shows that the BOM version is active.

SUMMARY

The above screenshots guide the user through the complete process of setting up BOMs for individual or grouped items. From releasing a new product to creating BOM, each one of these steps is explained in detail with helping subtitles and screenshots

The objective of Production Control

The performance of a company’s production control department has a significant impact on its overall success. The production control department is responsible for the following tasks:

- Raw materials, equipment, machinery, and labor are all provided.

- To plan the master scheduling per demand projections.

- The resources are utilized to the best of their abilities in a production order to keep the cost of production low and the delivery date on track.

- Determination of cost-effective manufacturing runs to lower setup costs.

- The operations of several sections/departments responsible for manufacturing must be coordinated properly.

To minimize manufacturing delays, provide consistent and timely delivery of raw materials at the desired location, in the specified quality and quantity.

Inspection of semi-finished, final goods, and quality control procedures ensure that the specific requirements are met.

It is also in charge of product development and design.

Thus, the primary goal of production control is to regulate and control the several operations of the manufacturing process in such a way that an orderly flow of material is maintained at all stages of production and that the items are produced in the right quality, quantity, and time with the least amount of effort and cost.

SUMMARY

Production control is gathering all the machinery, labor and tools to get production according to plan. A production control comes with several objectives, all of which are subjected to maintaining efficient production control quality and maintenance.

At Instructor Brandon | Dynatuners, we always seek innovative methods to improve your competitiveness and suit your Microsoft Dynamics 365 requirements. Our offerings are founded on defined procedures, industry experience, and product understanding. If you’re interested to consult with our technical solutions expert on how we may help you to renovate your production control by managing bills of material, don’t hesitate to Contact Us.

[sc_fs_multi_faq headline-0=”h2″ question-0=”What are the components of Bills of Materials in Dynamics 365?” answer-0=”Every line of the bill of materials (BOM) includes the product code, part name, part number, part revision, description, quantity, unit of measure, size, length, weight, and specifications or features of the product. ” image-0=”” headline-1=”h2″ question-1=”What are the uses of Bills of Material (BOM)?” answer-1=”During production, a manufacturing BOM is used. It specifies the components and assemblies required to make a shippable product, including packing and waste and things consumed throughout the manufacturing process.” image-1=”” headline-2=”h2″ question-2=”What is the difference between BOM (Bills of Material) & BOQ (Bill of Quantities)?” answer-2=”BOQ and BOM are valuable tools for project planners and contractors to understand the inventory needs. While BOM refers to the inventory list, which includes raw materials, parts, and components, BOQ refers to the total items needed to execute a project.” image-2=”” count=”3″ html=”true” css_class=””]

2737

2737