Supply Chain and Logistics Management

Get your materials from your vendors at right time for efficient production using Microsoft Dynamics 365 Transportation Management for Inbound Shipments

Get Materials from Vendors with Dynamics 365 Transportation Management

Transportation Management | Landed Cost | Logistics Service | Route Planning | Transportation Cost

Transportation expenses often equal or surpass the costs of storage, order entry, and customer service in most businesses. Freight transportation is the business lifeblood to the marketplace, and it has been a forerunner to the world’s shrinkage or “flattening.”

Logistics management has a larger effect on the bottom line as the supply chain gets more sophisticated and interconnected. Every dollar spent on transportation and materials management must be spent as efficiently as possible. Control must be the overarching theme when it comes to managing your mobility program. However, many companies do not devote the same resources to incoming transportation management as they do to outgoing transportation, resulting in a significant potential for efficiency and cost savings.

SUMMARY

Freight transportation is the business lifeblood to the marketplace, and it has been a forerunner to the world’s shrinkage or “flattening”. Logistics management has a larger effect on the bottom line as the supply chain gets more sophisticated and interconnected. Every dollar spent on transportation and materials management must be spent as efficiently as possible.

What are Inbound Shipments?

The raw goods and resources that a company receives from a supplier or vendor are referred to as inbound shipments. Inbound freight may also be thought of as the purchase of goods for your manufacturing facility, while outbound freight is the delivery of your finished product to a client. The network that delivers products or resources to your company is referred to as “inbound shipments.” Your inbound logistics network consists of everything you’ll need to carry, store, and deliver products from outside vendors to your company. What you do determines the goods you bring into your company. If you’re a manufacturing, inbound logistics may include raw materials, or completed goods if you’re in the assembly business. Inbound logistics, in its most basic form, refers to everything your company’s activities need to produce the completed product that you will ultimately sell.

Inbound logistics is both complicated and critical. There are a few important elements that contribute to the successful operation of incoming logistics operations. If your company needs raw resources to make specific products, you’ll need a consistent supply of those commodities to match your output. At the same time, if you don’t have the necessary storage, you don’t want too much raw material supplied. In most instances, you’ll want to have your raw material as soon as possible before using it. To avoid having an excess of unnecessary resources or products, you must adapt your inbound logistics network to your particular production cycle and storage capacity.

Streamlining your incoming logistics network helps you run your company more efficiently. To understand how to improve your incoming logistics network, you’ll need a complete image of every moving component and a thorough understanding of how it works. You must understand and optimize everything from receiving goods from suppliers to moving those things to your facilities and distributing them for your inbound logistics network to run as effectively as possible. Working with a third-party logistics (3PL) company is one method for companies to accomplish this. 3PLs specialize in designing and optimizing inbound logistics networks to guarantee that the flow of products and resources into your company matches your operational goals.

Click here to learn more about Logistics Management.

Consider a scenario in which you must increase production. What’s the best way to go about it? For assembly, manufacturing, receiving, and distribution, you may need to employ additional workers. More robust warehousing may be required, which may need new buildings, off-site storage, or equipment capable of handling larger amounts of products. You may need to engage closely with suppliers to arrange regular delivery in order to get the resources or products you need to fulfill demand. You may also need a sophisticated transportation management system to track resources and products as required across your network and to monitor the health of your incoming logistics network in real time.

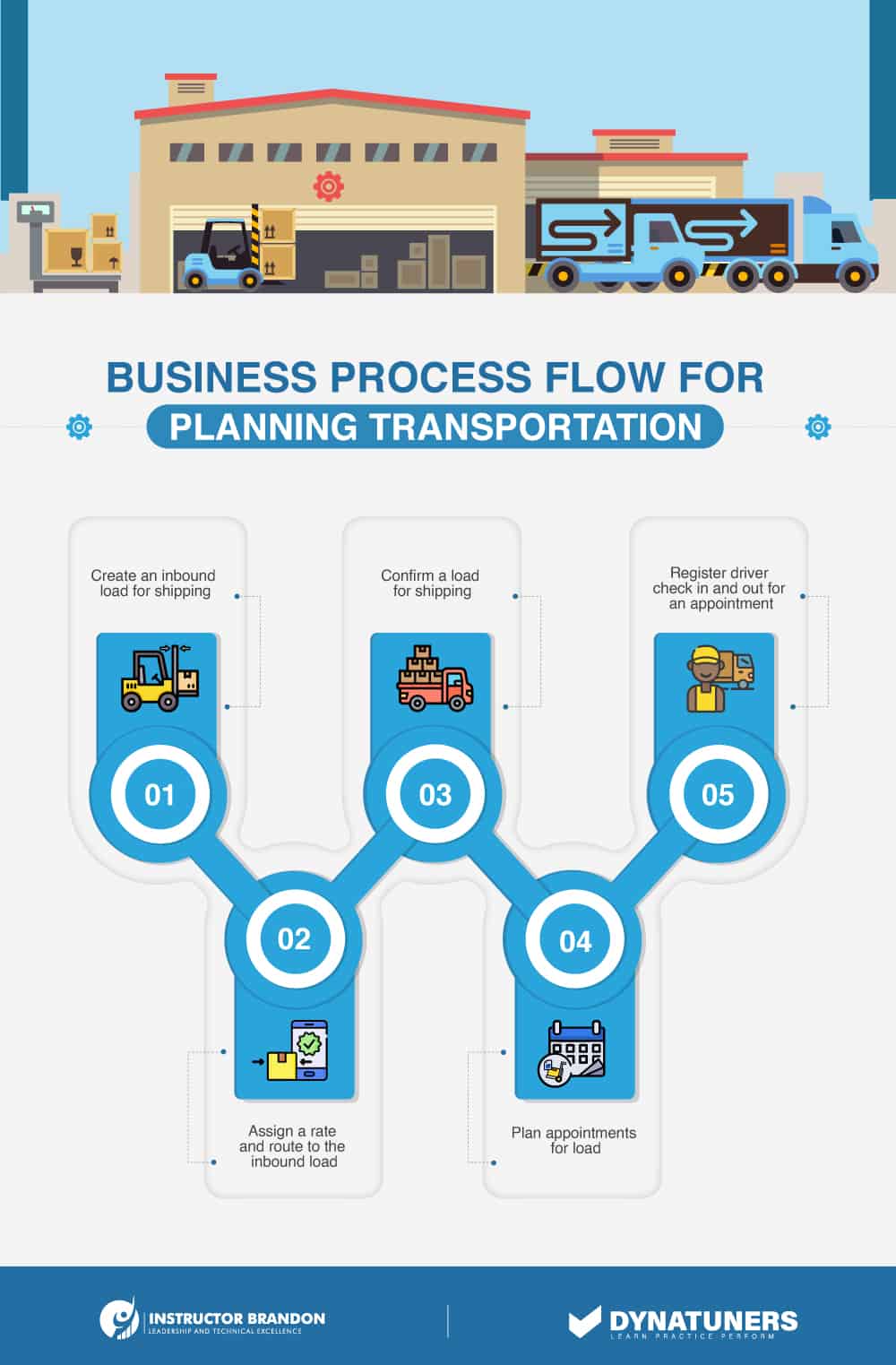

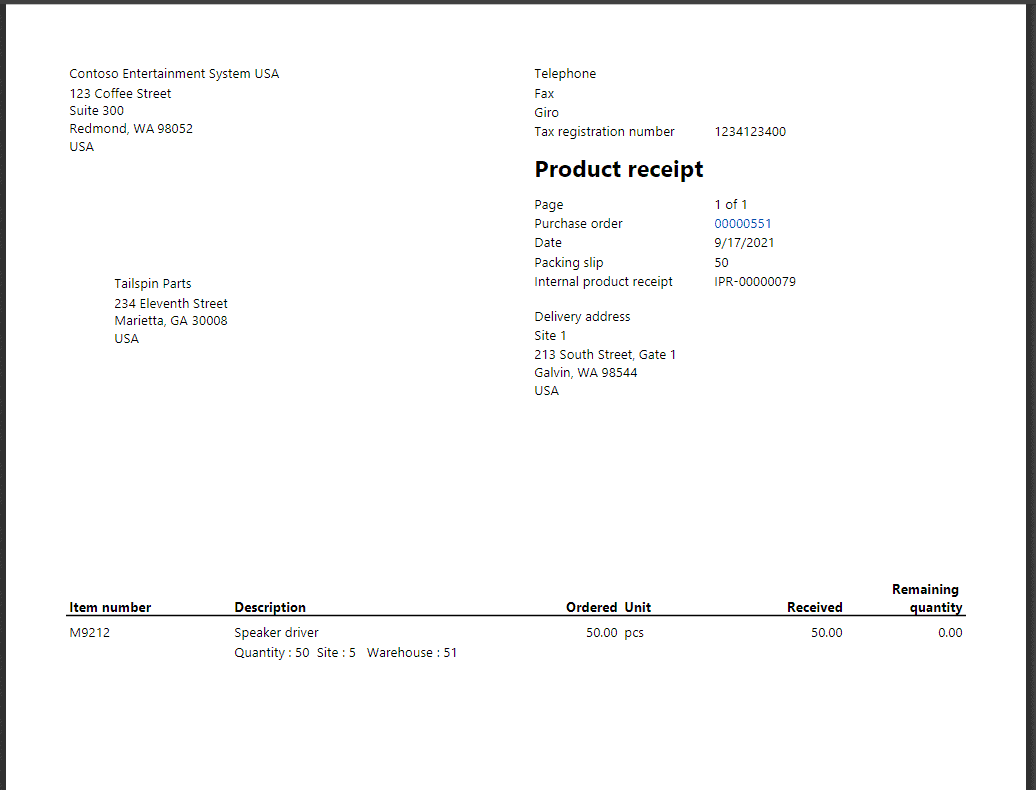

The business process flow for arranging transportation for an incoming cargo is shown in the diagram below.

It is feasible to do all of this in-house, but it may be quite costly. If you require ongoing efforts, devoting internal personnel to incoming logistics is also a better option. You just need a temporary solution for firms that only need to boost output momentarily, such as those that experience greater sales volume during the holidays. Working with a 3PL is one method for companies to build up their inbound logistics network in the near term. Without having to invest in personnel, equipment, or infrastructure, 3PLs can frequently scale a company’s inbound logistics network to meet its present requirements.

|

Sr. |

KPIs for Inbound Logistics | ||

| KPI | Description | Benchmark/Average time | |

|

1. |

Shipping time | Spot potential issues in your order fulfilment process | 87% |

|

2. |

Order accuracy | Monitor the degree of incidents | 95.8% |

|

3. |

Picking accuracy |

How many orders are picked without errors? | 97.2% |

|

4. |

Delivery time | Track your average delivery time in detail | 1-2 days |

|

5. |

Transportation cost | Analyze all costs from the order placement to delivery | 43% |

|

6. |

Warehousing costs | Optimize the expenses of your warehouse | 50% of the warehousing costs are order picking costs |

|

7. |

Number of shipments | Understand how many orders are shipped | 92% |

SUMMARY

Inbound freight may also be thought of as the purchase of goods for your manufacturing facility. Outbound freight is the delivery of your finished product to a client. Your inbound logistics network consists of everything you’ll need to carry, store, and deliver products from outside vendors. You must understand and optimize everything from receiving goods from suppliers to moving those things to your facilities. Working with a third-party logistics company is one method for companies to accomplish this. Without having to invest in personnel, equipment, or infrastructure, 3PLs can scale a company’s inbound logistics network.

Transportation Management

Companies are looking for methods to reduce operational expenses via business process improvements while prices remain under pressure. However, one operation with a proven high return-on-improvement rate is often overlooked: inbound transportation management.

Companies use inbound transportation management to take control of incoming freight from suppliers, combining loads, arranging continuous movements, and actively negotiating with carriers rather than paying for whatever shipping services the supplier selects. The buyer controls the carrier connection and is responsible for shipment planning, tendering, and payments, which is known as “freight collect“. More effective use of equipment and fuel, fewer less-than-truckload deliveries, and cheaper freight costs owing to greater volume result in direct savings. This may amount to millions of dollars each year, all of which goes directly to the company’s bottom line. Even yet, transportation cost savings are just the beginning of a far bigger payoff.

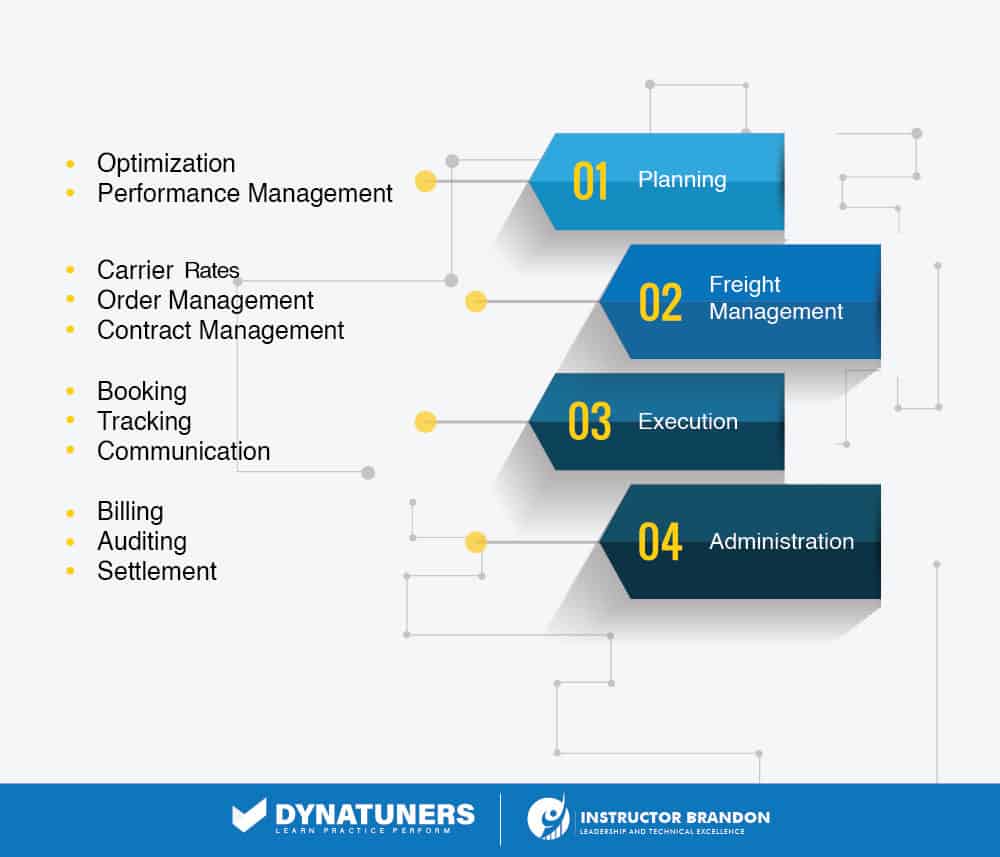

Main Functions of Transportation Management System

Up and down the supply chain, the larger value is achieved in the form of:

- Reduced lead times and reduced lead time variability

- Lower inventory levels

- End-to-end visibility from order to payment

- Management by exception

- More efficient receiving procedures

Inbound transportation programs have become much easier to implement thanks to new on-demand technologies that:

- Facilitate communications with carriers and suppliers

- Bridge internal gaps between procurement, transportation, and supply chain management

- Create reliable data and automate data flow among all parties

- Provide end-to-end visibility into order and shipment status

SUMMARY

Companies use inbound transportation management to take control of incoming freight from suppliers. More effective use of equipment and fuel, fewer less-than-truckload deliveries, and cheaper freight costs result in direct savings. Inbound transportation programs have become much easier to implement thanks to new on-demand technologies.

What Are the Advantages of a Transportation Management System for Shippers?

The ability to monitor more information about transportation management provides shippers with extra advantages via new data-driven capabilities. The following are some of the key advantages:

- Processes for auditing have been improved. TMS auditing features operate automatically as the system searches for instances of over- and under-billing, handles chargebacks for over-billing costs, and assures shippers get what they expect.

- Comparisons between carriers can be done in real time. Because of the intricacy, a comprehensive assessment of all alternatives is required to determine which carrier can offer the most cost-effective and timely service.

- Multi- or Omni-modal shipping is being used more effectively. Shippers have become used to package shipping’s low-cost characteristics and cost pass-through.

- Even quicker freight claim handling is possible with advanced systems. It’s a fact of life that things go wrong. Even the best-laid arrangements may go wrong, leaving the shipper to foot the bill. When an issue occurs, the transportation management system may be used to handle freight claims, i.e., cargo insurance, in order to prevent the dangers of increased freight expenditure.

SUMMARY

Transportation management systems provide shippers with extra advantages via new data-driven capabilities. TMS auditing features operate automatically as the system searches for instances of over- and under-billing. Claims can be handled quickly and cost-effectively via the transportation management system.

The Hidden Costs of Inbound Transportation

If you’re relying on your suppliers or vendors to handle all of your incoming transportation, you’re definitely paying more money on transportation than you need to. According to analysts, businesses overpay for incoming freight by one to two percent of their entire cost of products. This disparity between expected and actual incoming transportation costs may be summarized in a few words: suppliers’ transportation choices are not in your best interests. Some of your suppliers and vendors consider transportation to be a profit center, charging more than they spend for transportation. This is often done to protect against transportation process risks, such as fuel price rises or delivery delays that result in fines. Suppliers would naturally make choices based on their own business requirements, not yours, even if there are no deliberate markups in the cost of shipping. Manufacturers and distributors, for example, like to empty their docks at night. As a result, simply to get loads off the premises, they will prefer to ship utilizing the more costly less-than-truckload (LTL) option. When you consider multiple providers delivering LTL, the waste in terms of cost, efficiency, and fuel rapidly increases. For instance, a business may have five suppliers in close proximity who all send products on the same day. Instead of loading a single truck with goods from all five suppliers, the customer is obliged to pay for five individual LTL shipments, which is considerably more expensive. In other words, when the supplier controls the carrier connection and is in charge of shipment planning, routing, and optimization, the buyer loses any chance to combine loads and save money on transportation.

SUMMARY

Businesses overpay for incoming freight by one to two percent of their entire cost of products. Suppliers’ transportation choices are not in your best interests. Manufacturers and distributors like to empty their docks at night, leading to more expensive less-than-truckload (LTL) shipments.

Lead Time Reduction and Decreases in Lead Time Variability

Other cost reductions come from upstream and downstream supply chain operations, with inventory reduction being the most significant. This is why; companies may not know how much of their order has delivered until the vehicle comes up to the pier when suppliers manage incoming transportation. Uncertainty arises from a lack of insight into the progress of orders and shipments, which businesses usually mitigate by holding extra inventory. Inventory turns are also increasing, which has a direct effect on income. This is because the period between when an order is placed and when it is delivered, you may respond to changes in demand. You won’t be able to do anything about changes in the demand profile during this lag period if your suppliers control the delivery process. When you control the inbound transportation process, on the other hand, you may make route adjustments immediately before shipment to guarantee that goods are delivered to the regions with the highest demand. In conclusion, when you take control of your incoming deliveries, you can tailor them to your specific requirements. For example, you may decrease inventory by shortening lead times, synchronizing delivery with demand, and having materials or goods supplied within certain time frames.

SUMMARY

Uncertainty arises from a lack of insight into the progress of orders and shipments. This is why companies may not know how much of their order has delivered until the vehicle comes up to the pier. When you take control of incoming deliveries, you can tailor them to your specific requirements.

End-to-end Visibility

Today’s TMS systems go beyond transportation issues to provide everyone who needs an insight into the full order and delivery process. Procurement, warehouse, production scheduling, and supply chain managers, as well as transportation managers, fall under this category. It’s difficult to detect and fix process gaps that create supply chain unpredictability without insight into incoming freight and procedures. Due to the lack of visibility, a rush of phone calls, faxes, and e-mails are received, necessitating the hiring of full-time firefighters.

TMS solutions that provide end-to-end order visibility, on the other hand, allow businesses unparalleled control over orders in route. All players—suppliers, vendors, purchasers, and carriers—are working from a single source of truth to provide businesses with maximum visibility.

In conclusion, visibility advantages stem from the range of data accessible to interested parties throughout the supply chain, as well as the manner that data is presented in the context of addressing issues, evaluating performance, and enabling planning.

SUMMARY

Suppliers, vendors, purchasers, and carriers are working from a single source of truth. End-to-end order visibility gives businesses unparalleled control over orders in route. Visibility advantages stem from the range of data accessible to interested parties throughout the supply chain.

Management by Exception

The idea of management by exception goes hand in hand with supply chain visibility. It would be useless to monitor every contact point of every order as it travels through the supply chain under ideal circumstances in extremely large supply networks.

If a supplier, for example, is unable to complete a whole order or deliver at all, everyone who needs to know will be notified immediately. Procurement may restock or locate another source of supplies, warehouse employees can fill orders from safety stock, and production managers can change their plans based on when raw materials will be available.

SUMMARY

If a supplier is unable to complete an order or deliver at all, everyone who needs to know will be notified immediately. Procurement may restock or locate another source of supplies, warehouse employees can fill orders from safety stock, and production managers can change plans based on when raw materials will be available.

Improved Efficiency in the Receiving Process

Taking management of incoming supplies at the warehouse level has so many advantages that warehouse managers are often the first to propose or assume leadership of an inbound transportation project. Warehouse employees can significantly enhance customer service by controlling incoming supplies.

If the goods required to complete an order has been picked up, the warehouse manager knows when the truck will arrive and can prepare appropriately.

Other major advantages of using Transportation Management Systems for effective manufacturing are:

Cost-cutting on overheads

When incoming supply notification is automated, warehouses may employ fewer resources to complete the same amount of work or allocate resources to other value-added tasks. This is because phone or fax order status confirmation is replaced by real-time, precise information about incoming orders, and automated appointment scheduling allows for better planning.

A more evenly distributed workload

An on-demand TMS’s appointment scheduling feature may help the receiving process go more quickly and easily. Warehouse managers may level out flow through on a daily basis to make it more consistent, avoiding the usual Monday morning truck backlog.

There will be more cross docking

Warehouse managers can discover additional cross-docking possibilities with a greater understanding of all inbound cargoes. They may arrange incoming cargo to be cross docked after hours, maximizing asset usage while minimizing disruption to outgoing operations.

There will be less damage

Cross docking comes with the added benefit of reducing the time and touches needed to transfer goods to storage or materials from the dock to the assembly line. Inventory loss and damages are reduced as a result of this.

SUMMARY

Uncertainty arises from a lack of insight into the progress of orders and shipments, which businesses usually mitigate by holding extra inventory. TMS solutions that provide end-to-end order visibility, on the other hand, allow businesses unparalleled control over orders in route. Transportation Management Systems (TMS) enable warehouse managers to take control of incoming supplies at the warehouse level. TMS’s on-demand scheduling feature may help the receiving process go more quickly and easily.

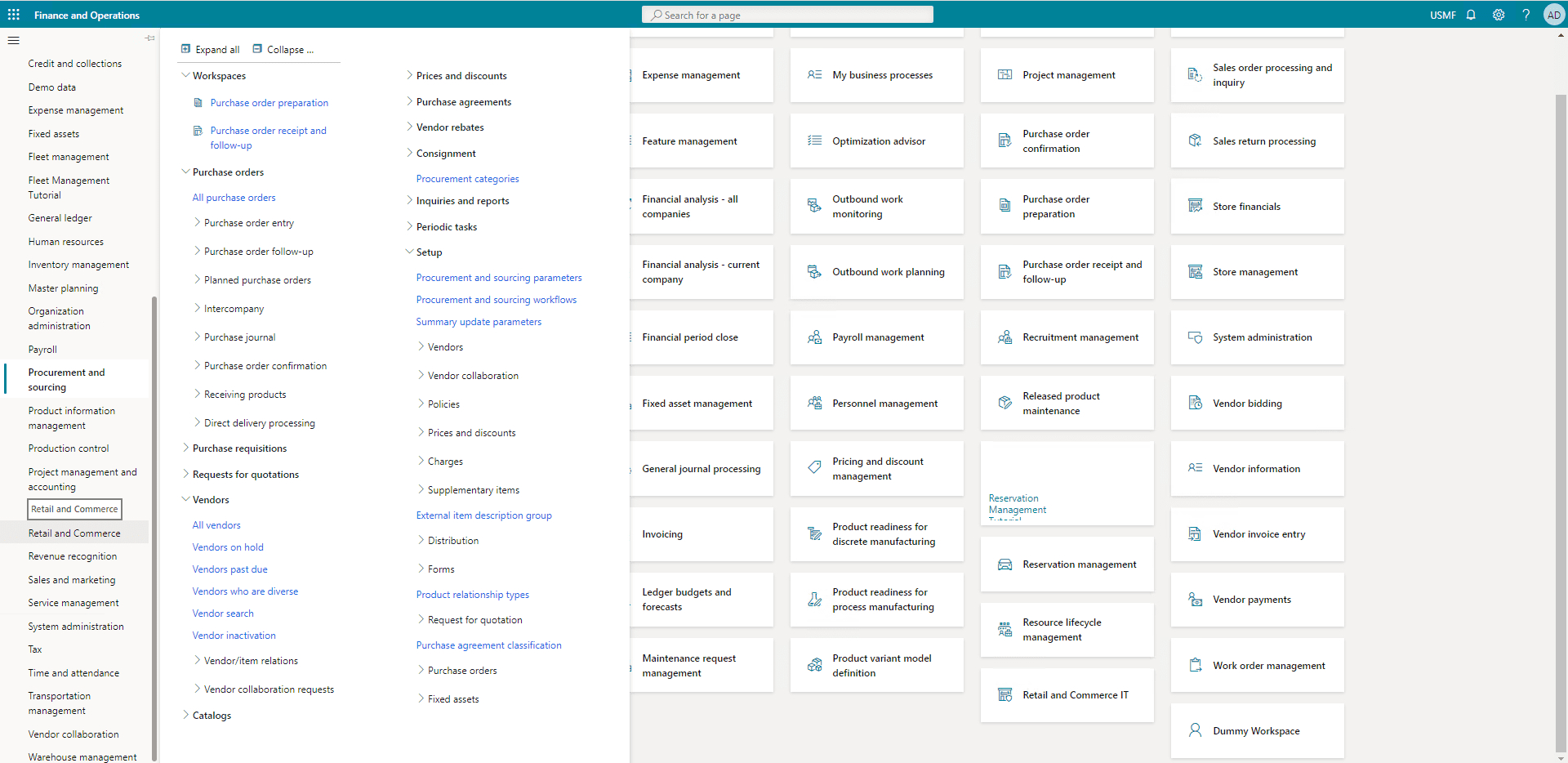

Inbound Shipments in Microsoft Dynamics 365: A Functional Walkthrough

Step 1

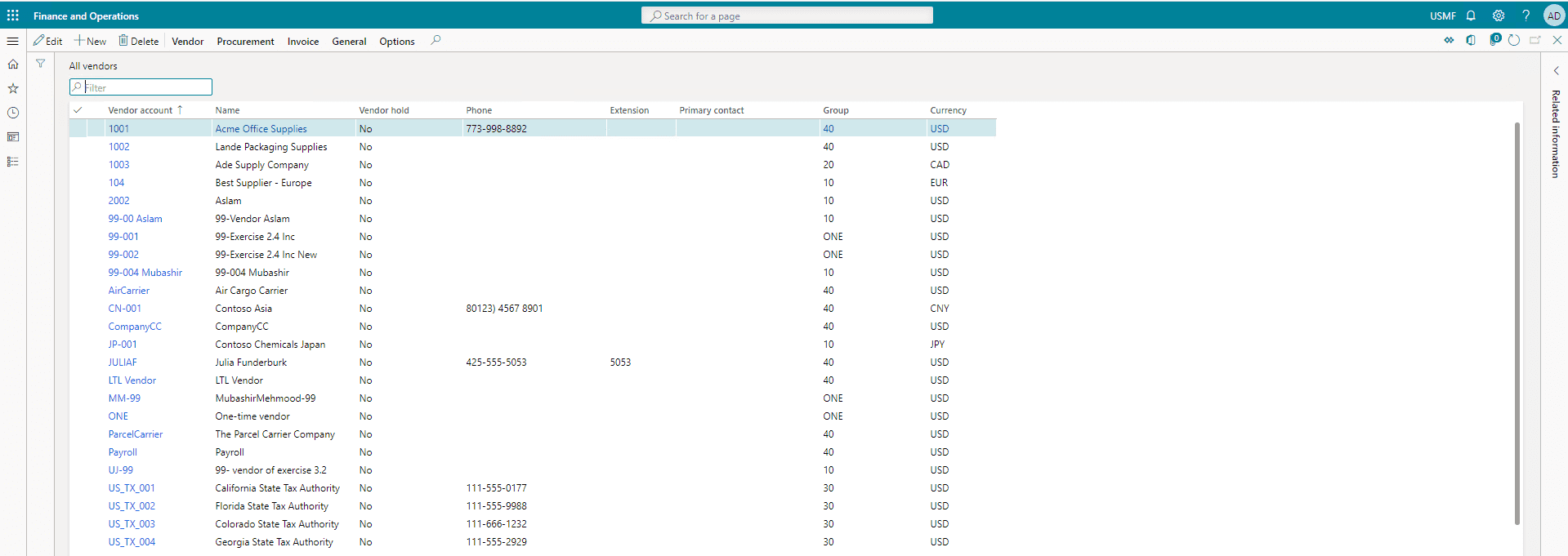

Go to Procurement and sourcing / Vendors / All vendors

Step 2

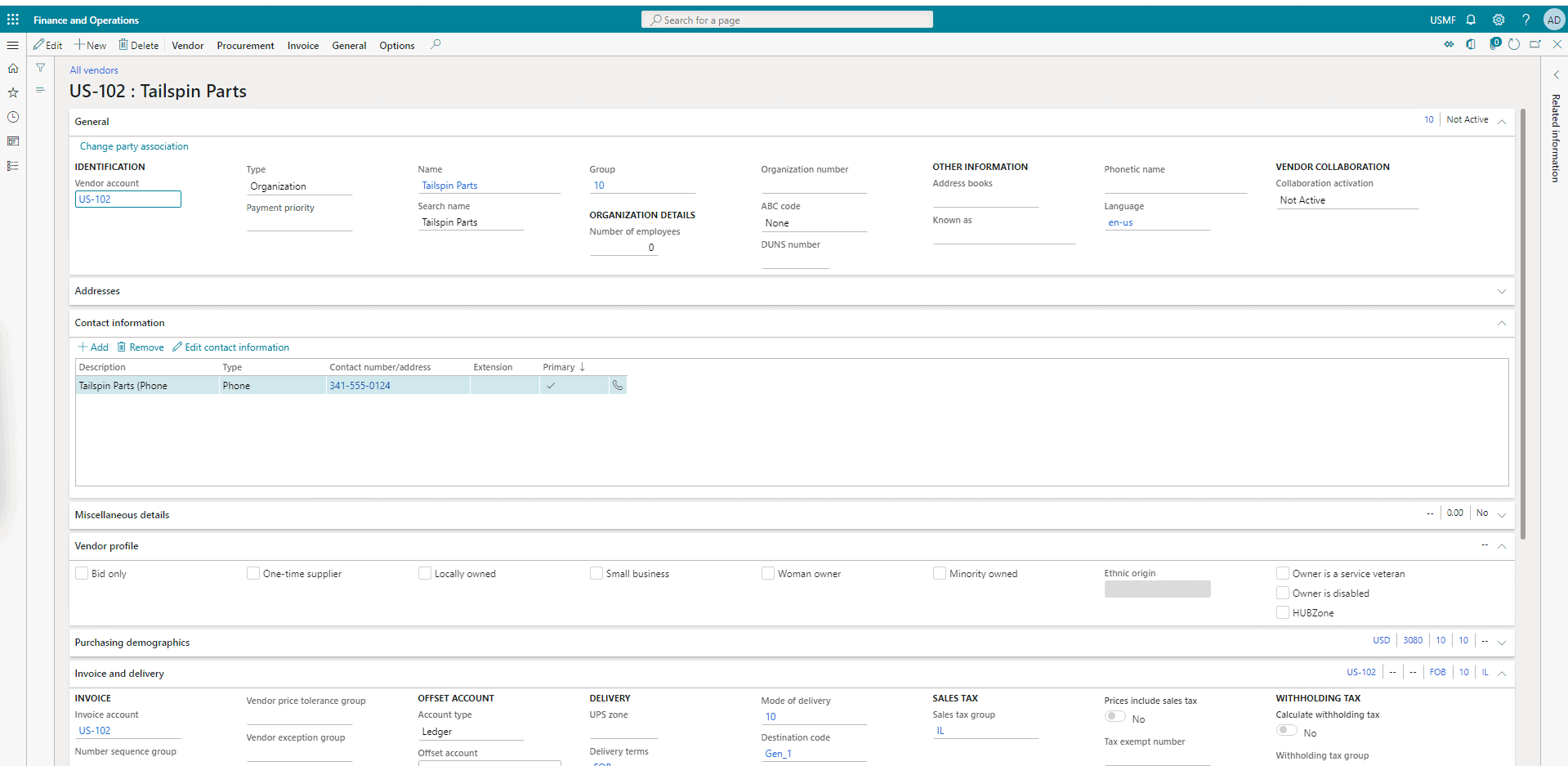

Select required vendor

Step 3

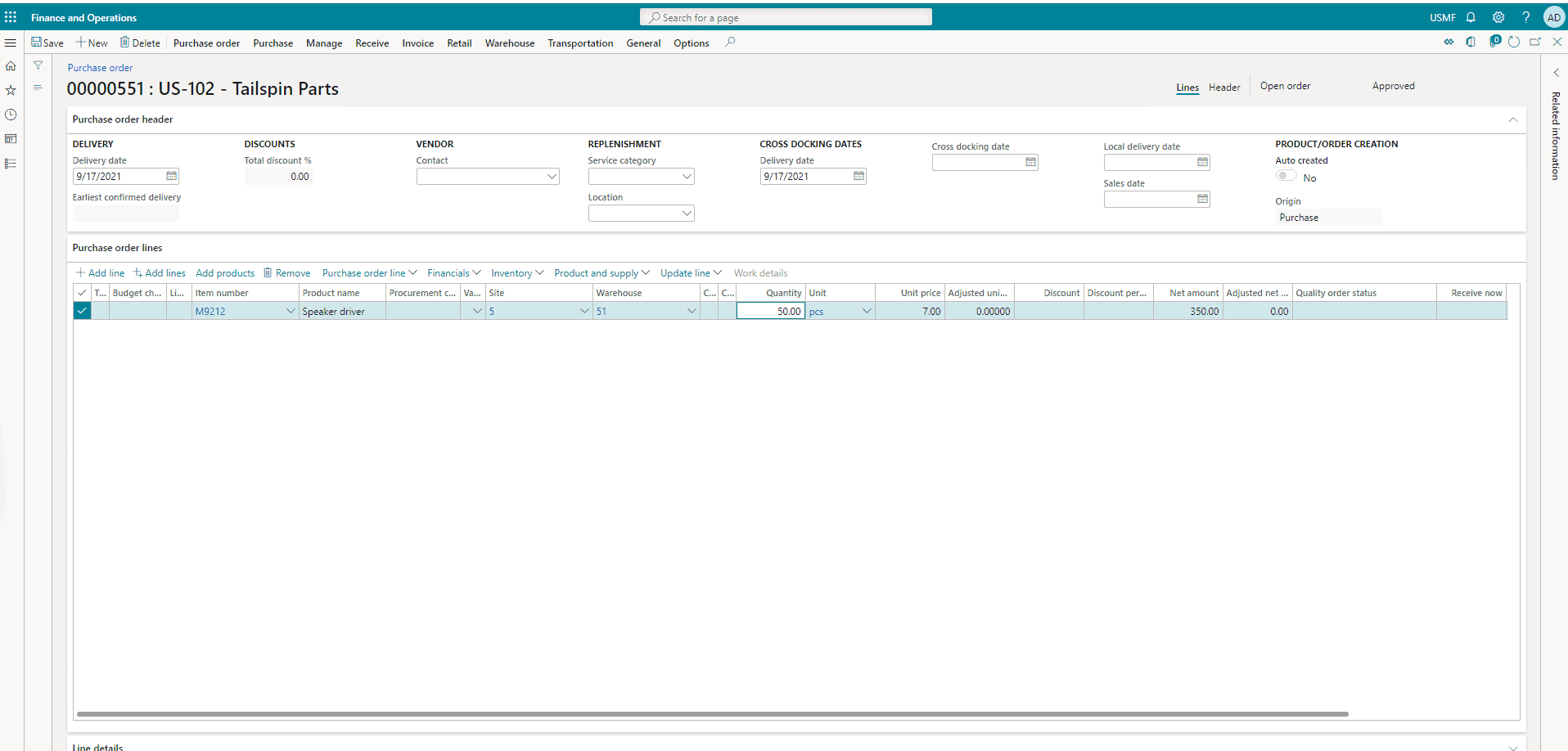

Go to Procurement / New / Purchase order in the action pane.

This step will lead to create a new purchase order. Add the item, site, warehouse and quantity.

Step 4

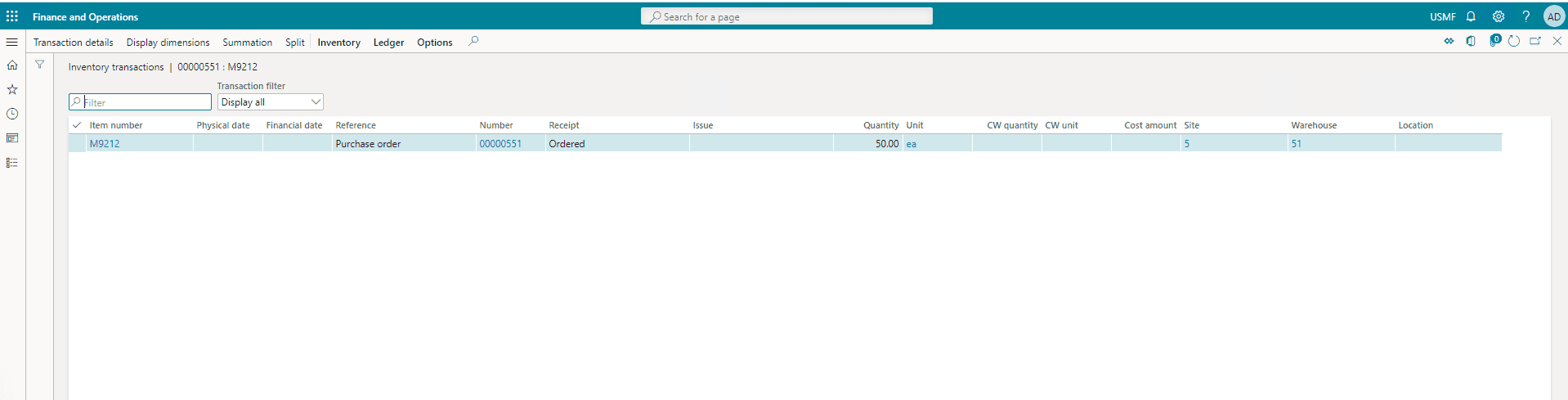

Click on Inventory / Transactions.

Step 5

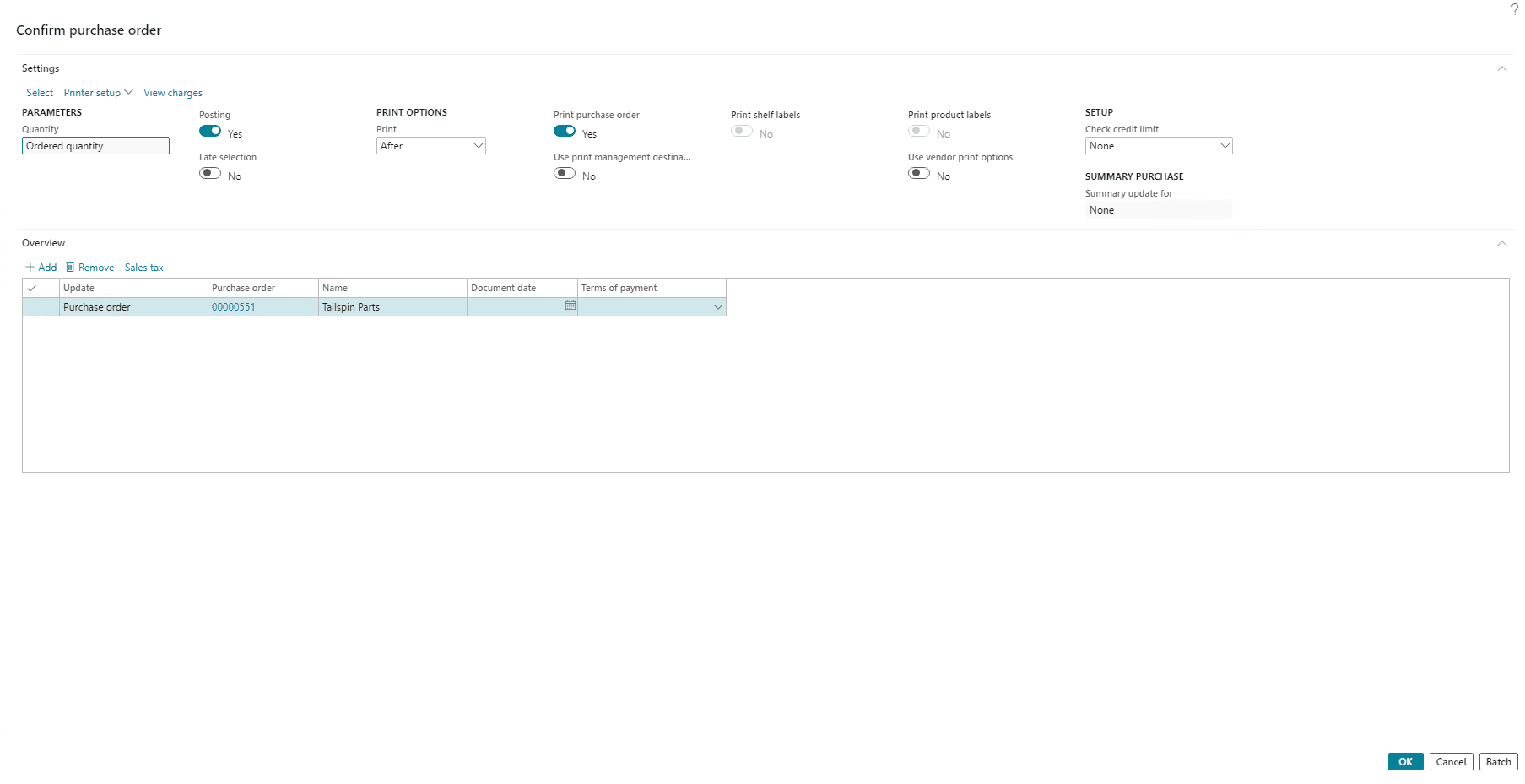

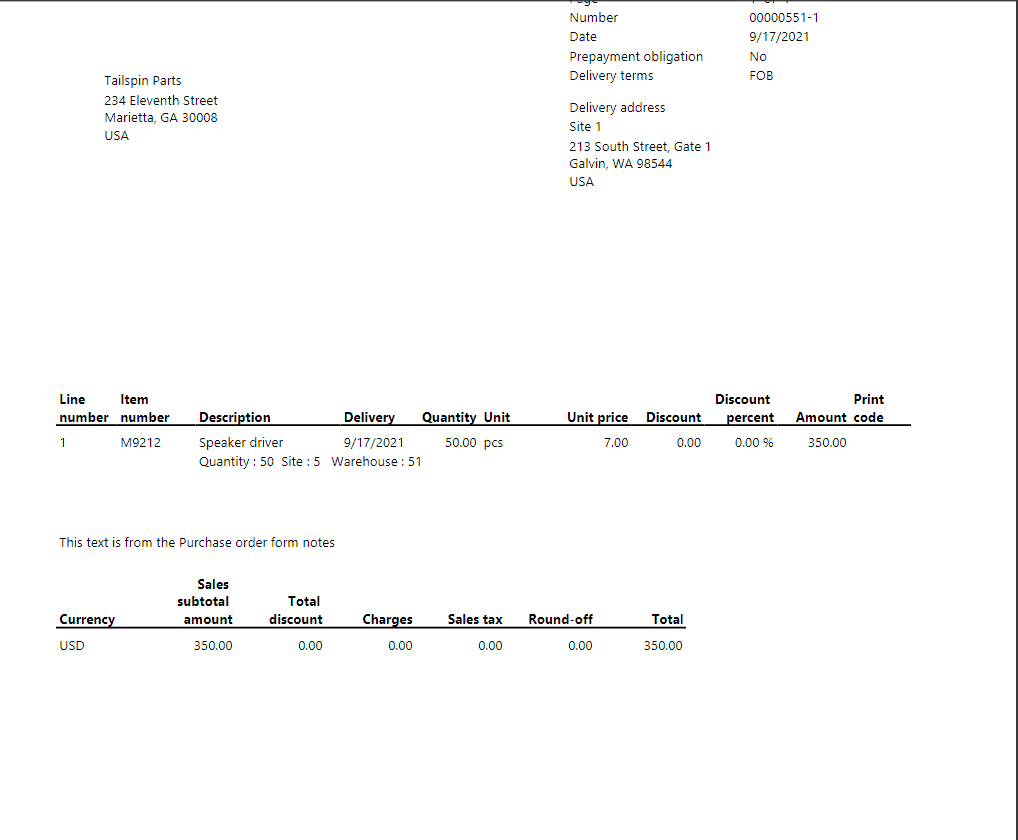

Now go to Purchase / Generate / Confirmation in the action pane

Step 6

Click on OK in the Confirm purchase order.

Step 7

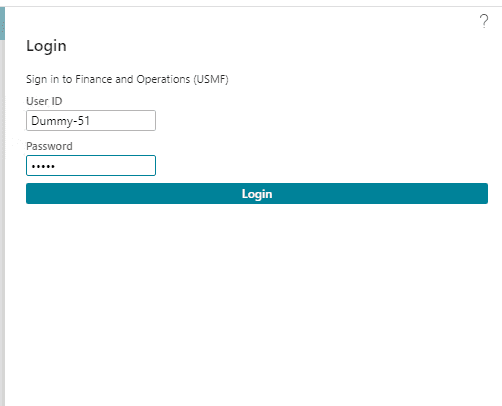

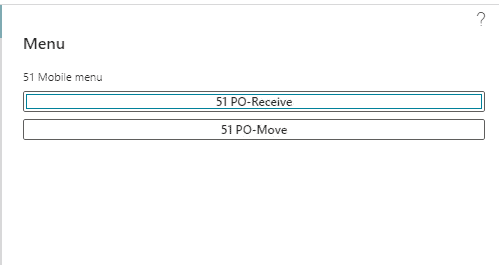

Now go to this link https://usnconeboxax1aos.cloud.onebox.dynamics.com/?f=WHSWorkExecute&cmp=USMF

To access mobile device for warehouse management.

Log in to Finance and Operations (USMF).

Step 8

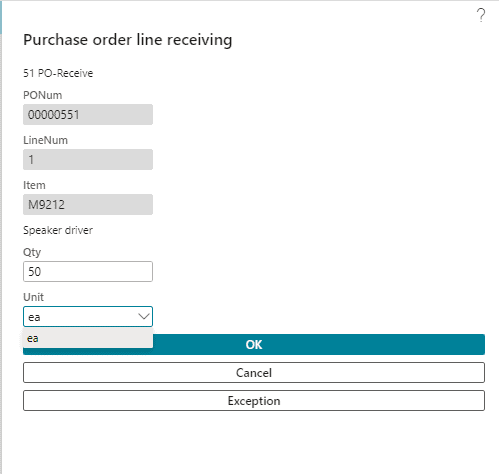

Enter the PO number, line number, and item

Step 9

After pressing Ok

System will show this message.

Step 10

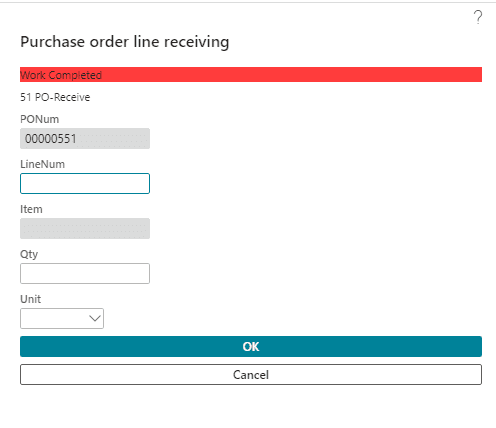

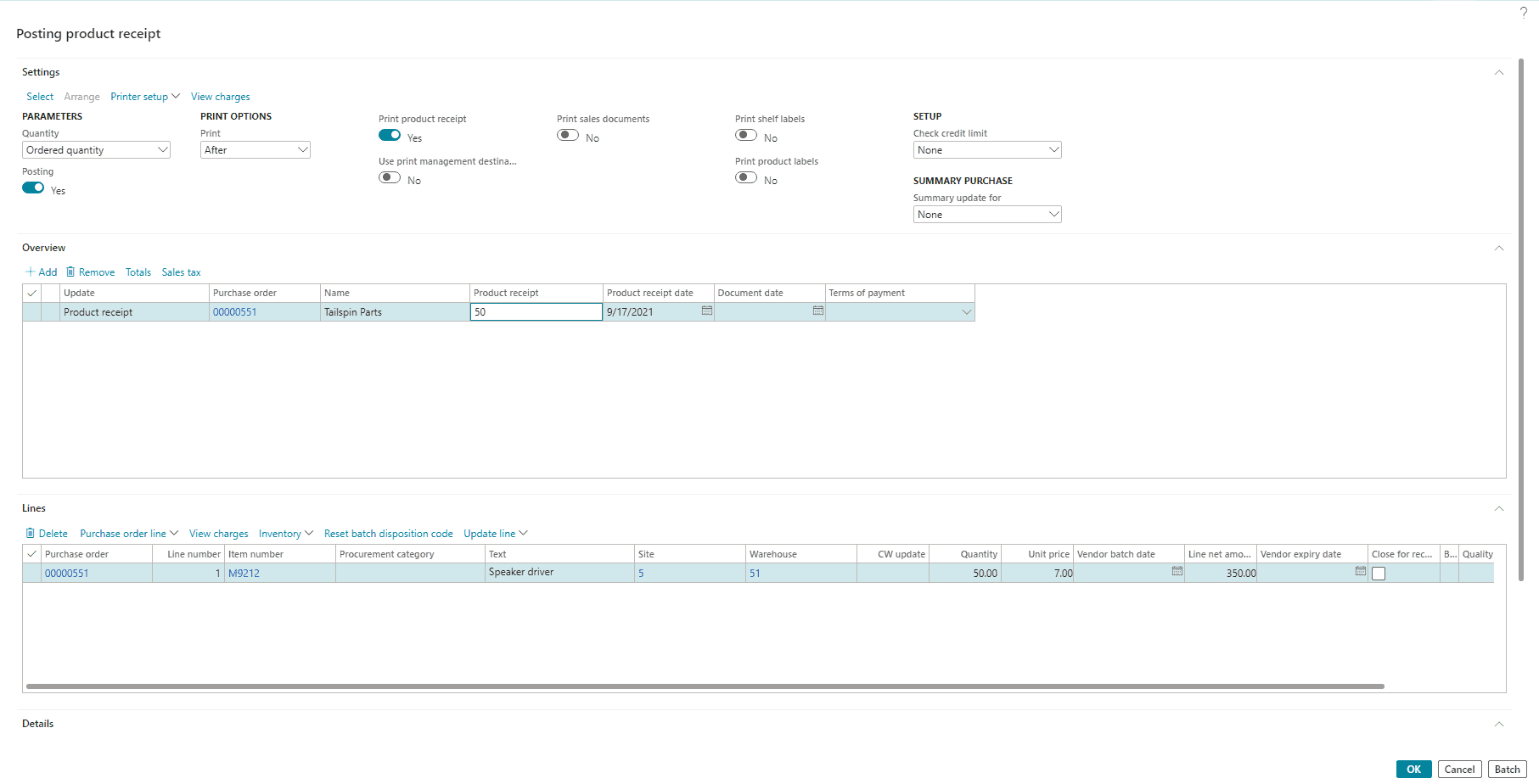

This time go to Sale order then Purchase order lines / Inventory / Transaction

The Receipt status has been changed to Registered

Step 11

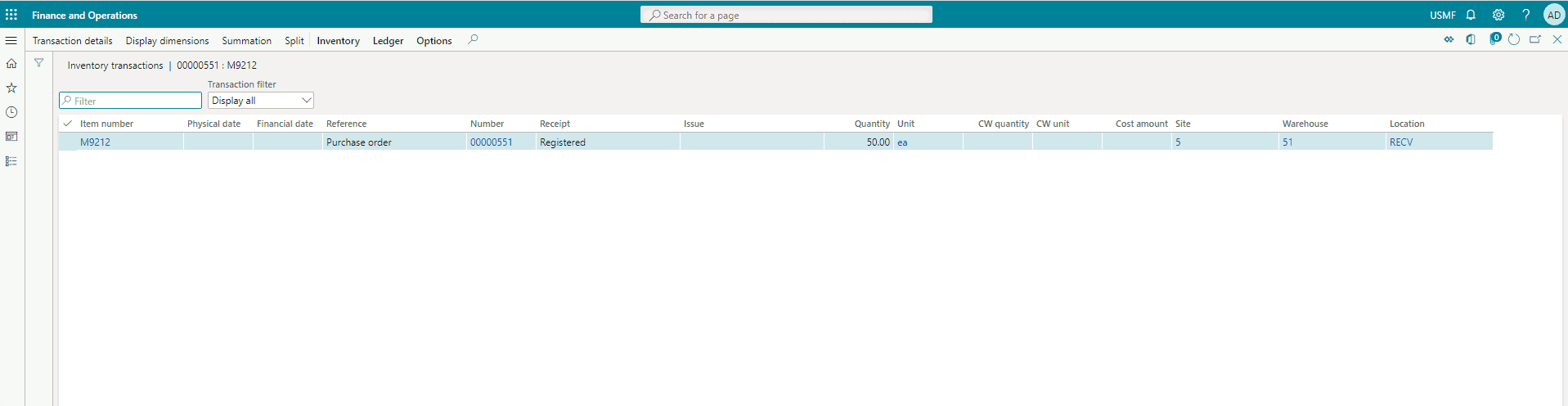

Click Receive / Generate / Product receipt

Step 12

Click OK

What is the best way to integrate Microsoft Dynamics 365 Technology with my Transportation Management and Inbound Shipments?

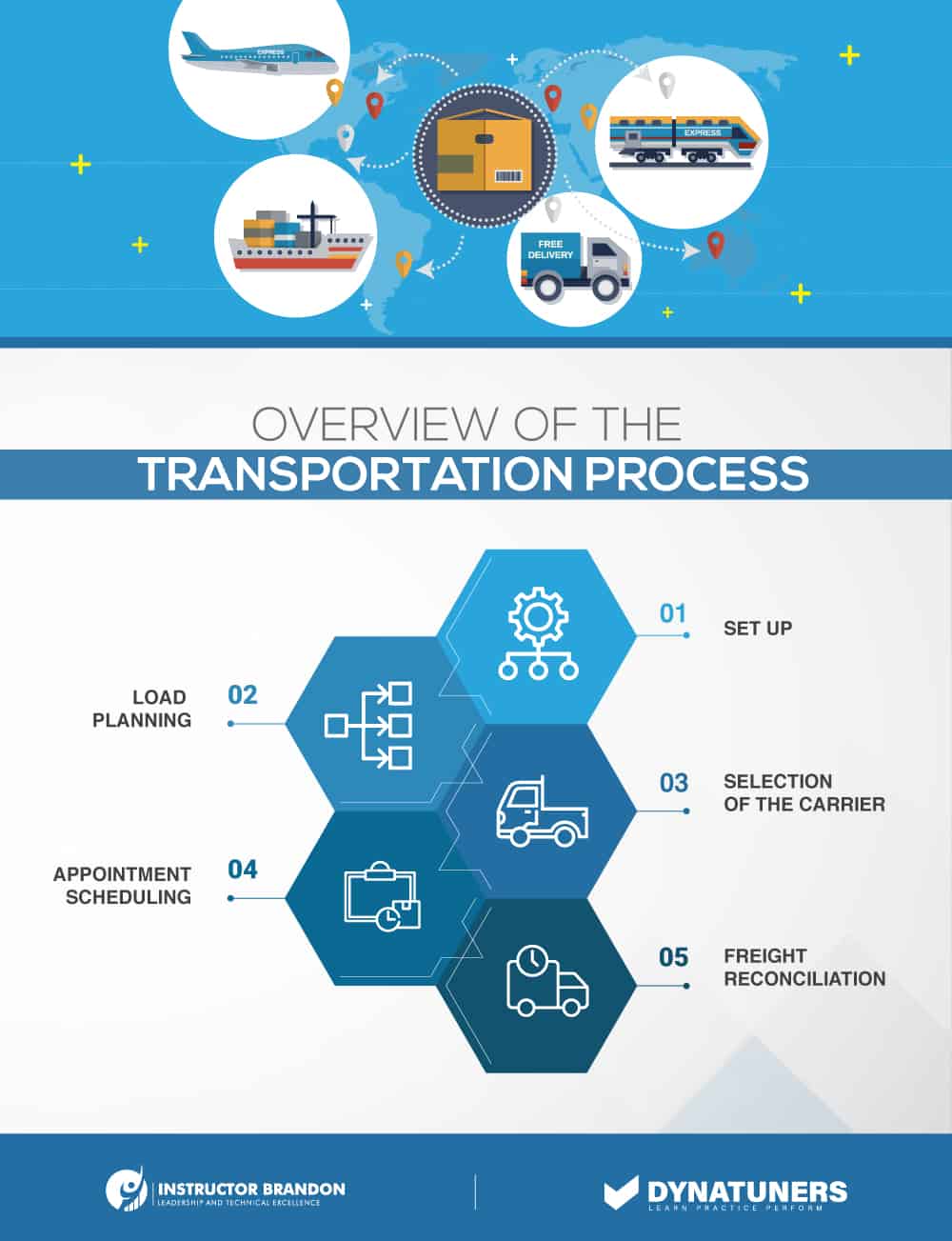

To arrange the transportation of ordered goods to your warehouse, utilize Dynamics 365 for Supply Chain Management. You may guarantee appropriate landing cost and precise costing by arranging item transportation and reception of the incoming load. Through improved financial and logistical insight into the extended supply chain, D365 enables precise and timely pricing of item transportation. Specific cost prediction also allows for better and more agile decision-making, which helps to reduce costing mistakes. You may increase item profitability, minimize internal follow-up calls from logistics, and enhance warehouse planning by using Dynamics 365 to arrange timely incoming transportation.

You can save transportation expenses by optimizing incoming logistics with Dynamics 365 for Supply Chain Management. Building strategic connections with your suppliers, utilizing a transportation management system (TMS) for dynamic freight pricing, or combining incoming freight deliveries are all ways to accomplish this. For example, online routing instructions can react to changes in the shipping environment, such as rate fluctuations. You may reduce rogue costs and remove non-authorized carriers by identifying optimum routes. A TMS may also provide you with insight into market prices, allowing you to obtain the best rates and expenses.

The transportation management feature in Dynamics 365 allows you to arrange incoming transportation effectively while guaranteeing on-time delivery and correct shipment. You may also save money by optimizing the shipment procedure depending on the due date, cost, and capacity of your equipment. D365 for Supply Chain Management provides end-to-end visibility of orders, payments, and deliveries, reducing lead times and improving transportation operations.

You can accomplish correct shipments in a timely way by evaluating all variables that may have a direct or indirect impact on transportation logistics. A single picture of all current carriers and how they compare to one another aids you in selecting the carrier network that performs at its best while saving time and money.

We suggest that you look into all of our Instructor Brandon courses and certifications so that you are informed of new technologies and choices for your company and career development.

SUMMARY

You can increase item profitability, minimize internal follow-up calls from logistics, and enhance warehouse planning with Dynamics 365 for Supply Chain Management. D365 provides end-to-end visibility of orders, payments, and deliveries, reducing lead times and improving transportation operations. The transportation management feature in Dynamics 365 allows you to arrange incoming transportation effectively while guaranteeing on-time delivery.

Improving Inbound Logistics Is a Crucial Component of Supply Chain Management

We know that a good inbound logistics process ensures that companies deal with the finest suppliers, and that an efficient outbound logistics process keeps customers satisfied, resulting in increased sales.

To improve efficiency, keep a close watch on your processes and establish standard operating procedures. Don’t be hesitant to rely on technology to get a better understanding of your whole supply chain.

You may adapt the tactics and approaches that work effectively for your company by emphasizing supply chain management, regardless of the size of your firm.

SUMMARY

A good inbound logistics process ensures that companies deal with the finest suppliers, and that customers are satisfied. To improve efficiency, keep a close watch on your processes and establish standard operating procedures. Don’t be hesitant to rely on technology to get a better understanding of your whole supply chain.

At Instructor Brandon | Dynatuners, we always seek innovative methods to improve your competitiveness and suit your Microsoft Dynamics 365 requirements. Our offerings are founded on defined procedures, industry experience, and product understanding. If you’re interested to consult with our specialists on how to optimize your transportation management processes, don’t hesitate to Contact Us.

[sc_fs_multi_faq headline-0=”h2″ question-0=”What is the essence of inbound transportation? ” answer-0=”These words relate to how products are transported and moved along the supply chain. Inbound logistics refers to the receipt of goods and raw materials from suppliers, whereas outbound logistics refers to the delivery of commodities and products to the final customer. ” image-0=”” headline-1=”h2″ question-1=”What is transportation management and why does it matter? ” answer-1=”Users may get real-time tracking and order information from transportation management systems. Companies have comprehensive and reliable information to pass on to customers, enhancing customer service and giving insight throughout the supply chain. ” image-1=”” headline-2=”h2″ question-2=”Can you explain the distinction between incoming and outbound shipments? ” answer-2=”Outbound logistics deals with transporting goods and products out to consumers, whereas inbound logistics deals with bringing supplies or resources into a company. Both are mainly focused on the transportation of commodities. Inbound, on the other hand, is all about receiving, while outbound is all about delivering. ” image-2=”” count=”3″ html=”true” css_class=””]

2678

2678