Dynamics 365 Tutorials, Microsoft Dynamics 365 Developer (F&S) Training Series, Supply Chain and Logistics Management

Learn How to Configure Ownership of Consignment Inventory based on Production Demand with Dynamics 365 Supply Chain Management

Configure Ownership of Consignment Inventory with Dynamics 365

Inventory Consignment | Warehouse Management | Inventory Tracking | Purchase Orders | Inventory Control | Financial Inventory

The majority of supply chain management professionals know the advantages and disadvantages of consignment inventory. Whether your business is the seller supplying the consignment inventory or the client receiving it, some concerns must be addressed in the inventory agreement. Both customers and suppliers are concerned with inventory invoicing and the ultimate transfer of ownership of consigned merchandise from one party to another. Both parties must be fully informed of their respective responsibilities about how and when consigned goods will be invoiced and when ownership of the inventory will be transferred from the vendor to the customer. If neither party defines these obligations in advance, there will be complications after the contract is signed.

When it comes to selling items, the consignment model of inventory management necessitates collaboration between various businesses and legal entities. The model comprises a retailer that stores and sells the items mentioned above and one or more suppliers who possess the commodities mentioned above. The consignee obtains a percentage of the proceeds from the sale of the items, while the consignor receives the remainder.

Inventory consignment refers to goods kept and sold on behalf of another firm. Consigned inventory is stored in warehouses dedicated only to the supplier’s stock for sale to the merchant.

While consignment products are housed in the retailer’s warehouse, the consignor retains ownership of them. Therefore, the consignee is responsible for maintaining and selling them. Additionally, the consignor counts these items in their physical inventory counts.

SUMMARY

Goods retained and sold on behalf of another company are referred to as consigned inventory. Consigned inventory is housed in warehouses solely devoted to the supplier’s for-sale goods. Both parties should know how and when committed products will be billed.

The Advantages of Consigned Inventory

Consignment inventory has many advantages for both the supplier and the retailer.

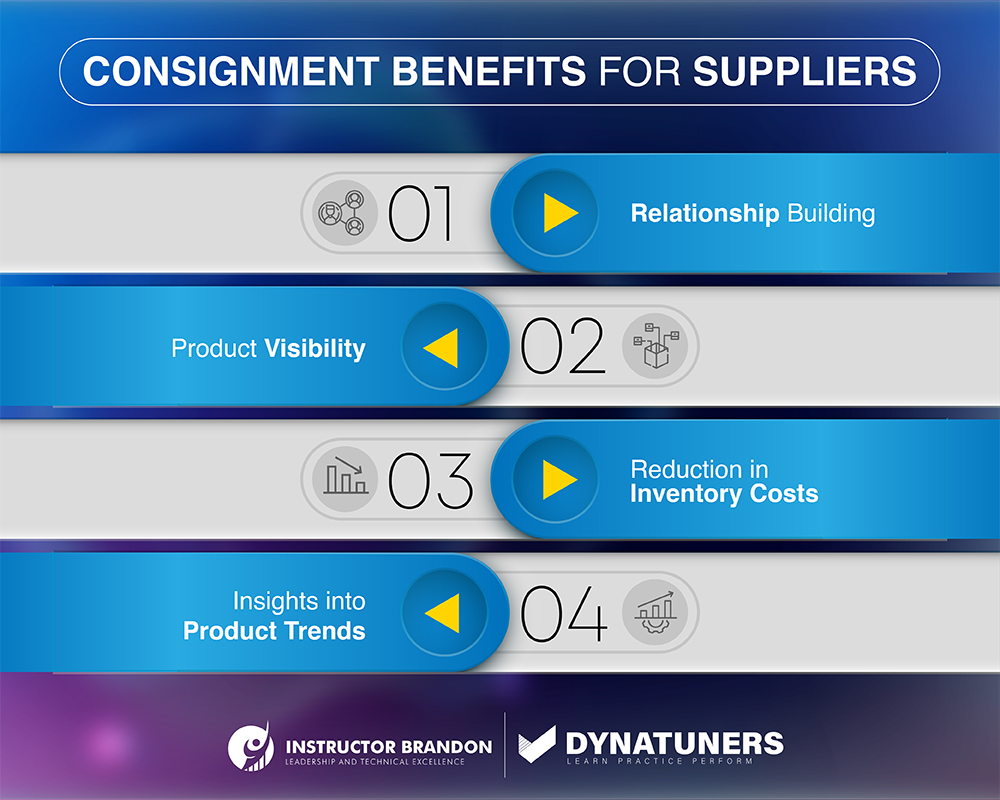

Suppliers Benefit from Consignment

- It helps in establishing sustainable relationships. Consignment necessitates collaboration and continuous interaction between suppliers and merchants. This strengthens their capacity to collaborate and develop sales for one another.

- Provides visibility for the product. For example, via consignment, a supplier’s goods may reach more clients than they might through typical distribution techniques.

- Inventory expenses are reduced. You should maintain sufficient inventory to support sell-through and any safety or anticipation stock. If you’re experiencing inventory problems, it may be time to use the inventory cycle count approach. Keeping a massive inventory of items is costly. With consignment, the retailer is responsible for all storage expenses.

- Provides insight into emerging product trends. For example, suppliers may watch the sales of their committed inventory to see which goods convert and for how long. This enables a supplier to invest in the right product and maintain the most profitable raw material inventory.

Consignment Benefits for Retailers

- Expands product selection. When clients have presented the most incredible product selection, sales improve. Consignment enables them to get a diverse array of unique items at a low cost. Consignment is also an excellent source of items for subscription boxes.

- Pay only for products sold. Unlike regular inventory, consignment inventory is only paid for when purchased by a consumer. This enables retailers to retain an ample safety supply at a low cost.

- Restocking inventory is primarily the responsibility of the supplier. Suppliers stand to lose a great deal if their product is back ordered since they are not paid beforehand. This requires suppliers to monitor stock levels and attempt to maintain them at the retailer’s ideal level.

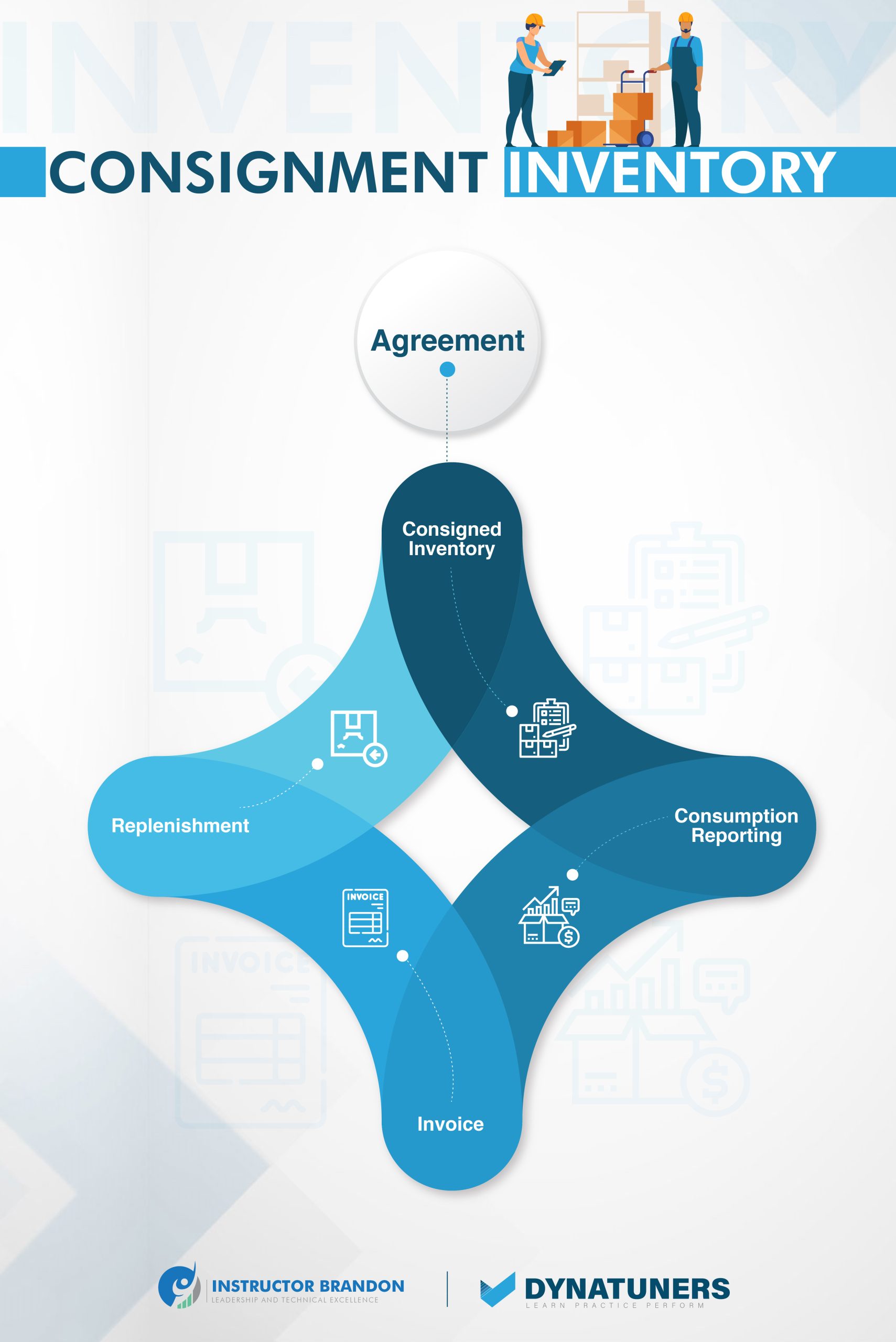

How Consignment Inventory Works?

Here is an example of how consignment inventory works. Assume Jane, an artist, wants to sell her work at her favorite downtown store. The store features handpicked work from local artists in addition to some of their own branded things. Jane wants to begin by evaluating two products: a set of greeting cards and a poster. So she strikes a deal with the retailer and gives over fifty greeting cards and one hundred posters. The business owner is passionate about her job and is thrilled to offer the goods to round out her collection.

Jane’s posters were completely sold out in less than a month! Her greeting cards, on the other hand, are experiencing some difficulties. It has been 60 days (the period specified in their agreement), and she has sold just 30 of the 50 sets. The business owner returns the remaining twenty items that did not sell.

In general, the consignment transaction was a success. Jane and the business owner both profited. Next, Jane must either devise a new method of selling the greeting cards or create a more enticing design.

SUMMARY

Consignment allows shops to get a wide variety of one-of-a-kind things at a moderate cost. Consignment inventory, unlike ordinary inventory, is only paid for when a customer buys it. Consider employing the inventory cycle count method if you’re having inventory issues. Because suppliers are not paid in advance, they stand to lose a lot if their product is back-ordered. Consignment allows merchants to keep an extensive safety stock for a low price.

The Concept of a Consignment Warehouse?

Consignment warehousing is any facility established by a supplier purely to store goods on consignment for a retailer. It is often located on or near the retailer’s premises to provide fast and straightforward access to the items. A consignment warehouse does not contain retailer-owned merchandise. As with just-in-time inventory, this minimizes merchants’ storage expenses.

While the phrases vendor-managed inventory (VMI) and consignment stock are sometimes used interchangeably, they are not synonymous. The ownership of items, the location of warehouses, and how transactions are handled are all distinctions between these two inventory procedures.

Vendor Managed Inventory (VMI)

The vendor/supplier oversees the inventory supply under the vendor-controlled inventory model, but the retailer owns it. While the store holds the inventory, they are not responsible for its administration, upkeep, or purchase. Vendor-controlled inventory and consignment inventory have several commonalities and distinctions. Both VMI and consignment inventory management need communication between the retailer and seller to exchange sales information. By establishing a good partnership, both the supplier and retailer benefit more from both approaches. However, consignment inventory is the supplier’s property, but vendor-managed inventory is the seller’s property. This implies that suppliers have a more significant stake in a consignment approach.

Get a hands-on, real learning experience with us, enroll now.

| Issues Within Consignment Inventory Agreements | |||

| Damage to Inventory | Invoicing Customer Usage | Transfer of Ownership from Vendor to Customer | If there is no transfer of ownership, then |

|

|

|

|

SUMMARY

A facility set up by a supplier solely to hold items on consignment for a retailer is known as consignment warehousing. Retailer-owned goods are not found in a consignment warehouse. Although the shop owns the merchandise, it is not responsible for its management, maintenance, or acquisition.

Consignment Inventory in D365

One of the glaring gaps in past versions of the Dynamics 365 system’s supply chain management functionality has been the inability to account for goods that your organization did not own. With supply chains becoming leaner, it might be considered a fundamental necessity to access commodities when you need them without tying up your financials by purchasing them far in advance. This prerequisite includes the necessity that your fully integrated ERP system support this – which it now does.

This new capability targets inbound consignment, namely raw material consignment in a manufacturing scenario. If, on the other hand, your firm is wholesale or retail, do not quit reading now! All this implies is that greater automation is possible when processing vendor-owned commodities at your facility, assuming the resource is a raw material used in production. However, it is entirely competent and straightforward for anybody to build, given the features.

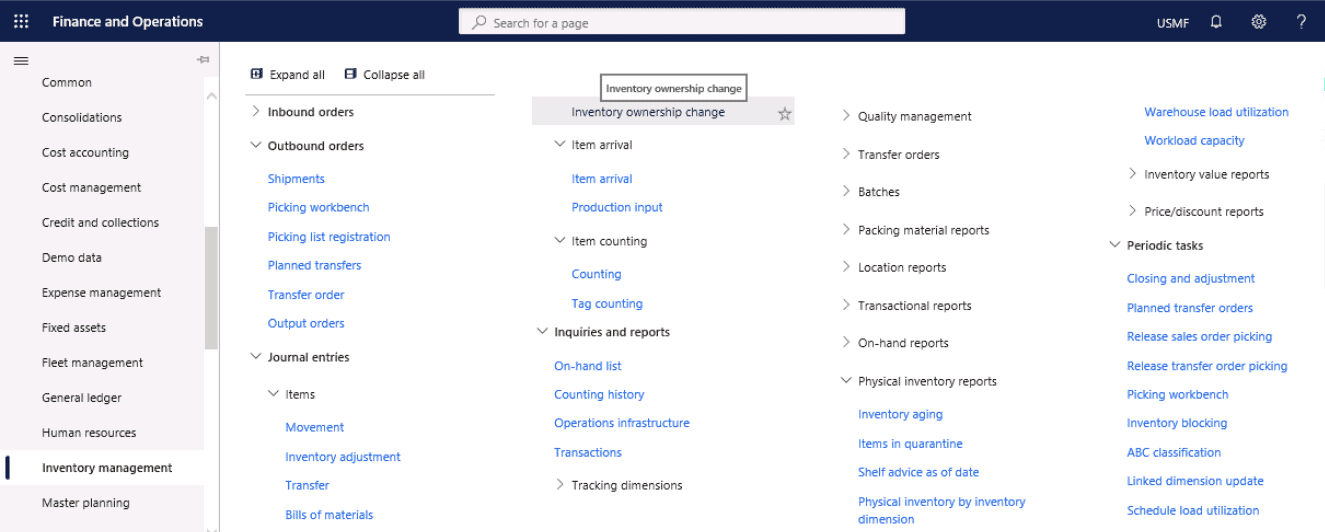

Change the Ownership of Consignment Inventory Based on Production Demand in Microsoft Dynamics 365

When demand for consignment goods exceeds supply, this technique demonstrates how to transfer ownership of consignment inventory from the seller to your legal company. This ownership change is accomplished by creating and publishing an inventory ownership change log. Ownership change log lines may be written manually or, as seen in this clip, automatically depending on current production needs. Typically, this role is performed by a shop floor supervisor. This approach may be used with the USMF demo data firm or your data. If you’re utilizing your data, ensure that you have the following prerequisites: a journal name for inventory ownership changes, physically recorded vendor-owned on-hand inventory, and one or more production lines for the material.

Do you want to learn more on how to create consignment replenishment orders, check out our blogs.

SUMMARY

This Dynamics 365 system’s supply chain management feature is aimed towards incoming consignment, namely raw material consignment. In Dynamics 365, change the ownership of consignment goods depending on production needs. This approach explains how to transfer ownership of consignment inventory from the vendor to your legal organization when demand for consignment products exceeds availability.

Functional Walkthrough of Ownership of Consignment Inventory

Change the ownership of consignment inventory based on production demand

Step 1

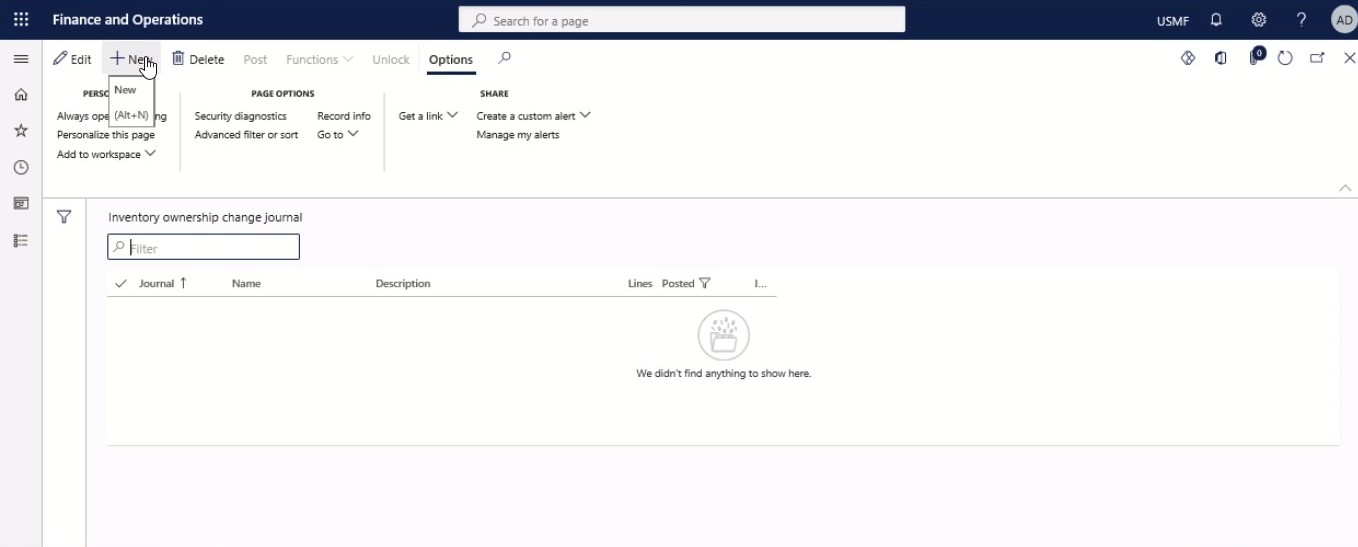

Go to Inventory management > Journal entries > Items > Inventory ownership change.

Step 2

Click New.

Step 3

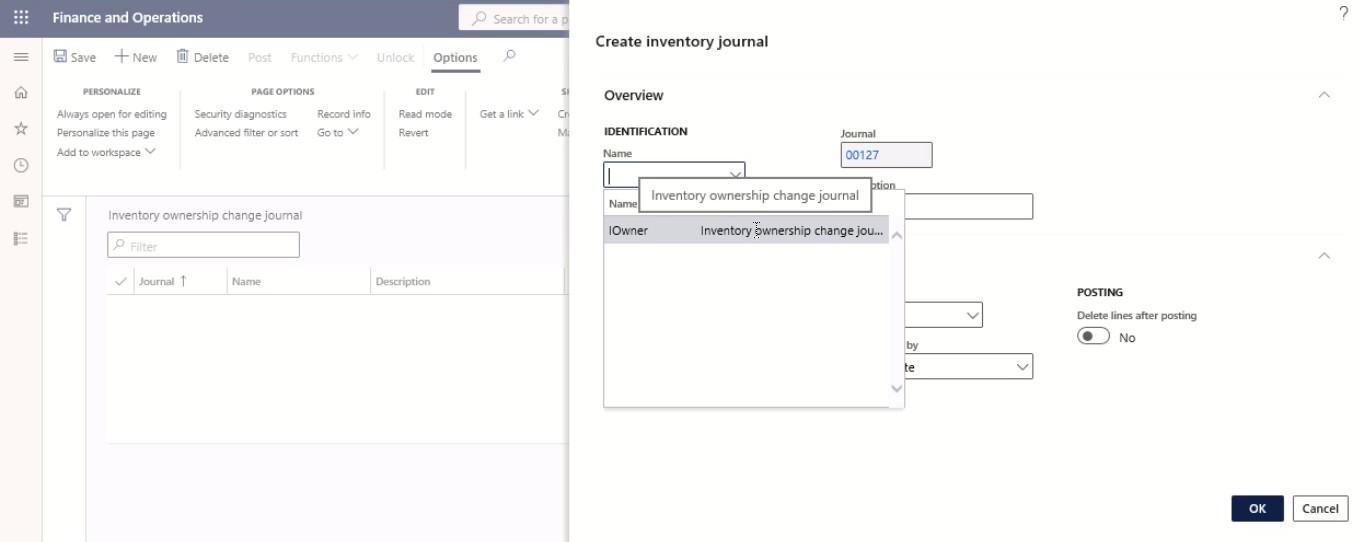

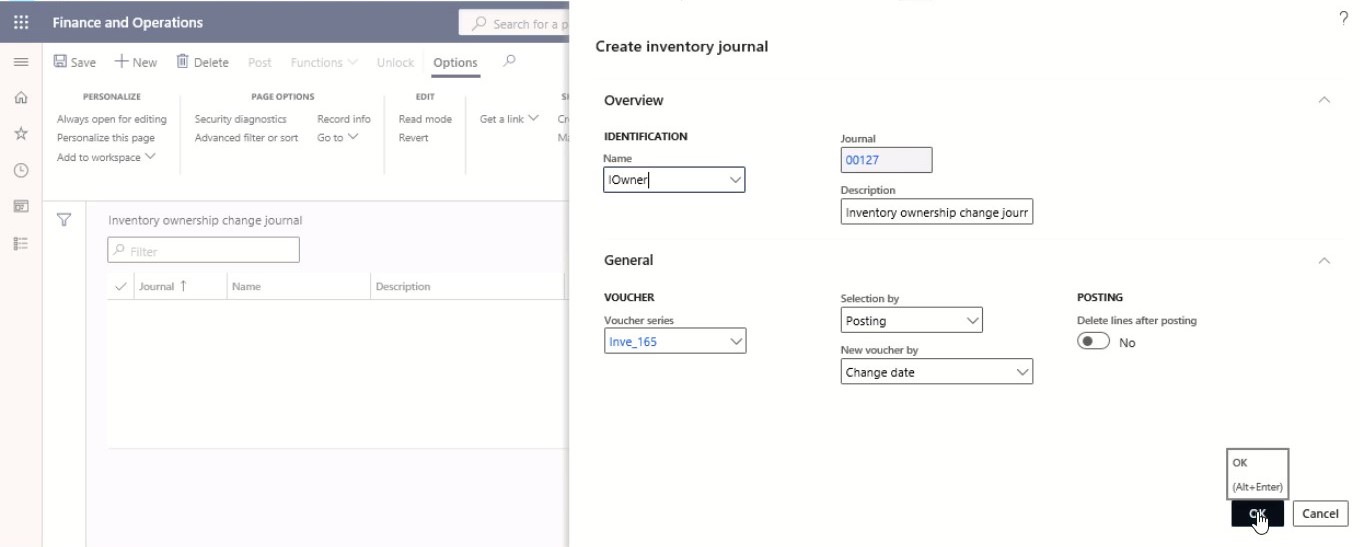

In the Name field, enter or select a value.

Step 4

Click OK.

Step 5

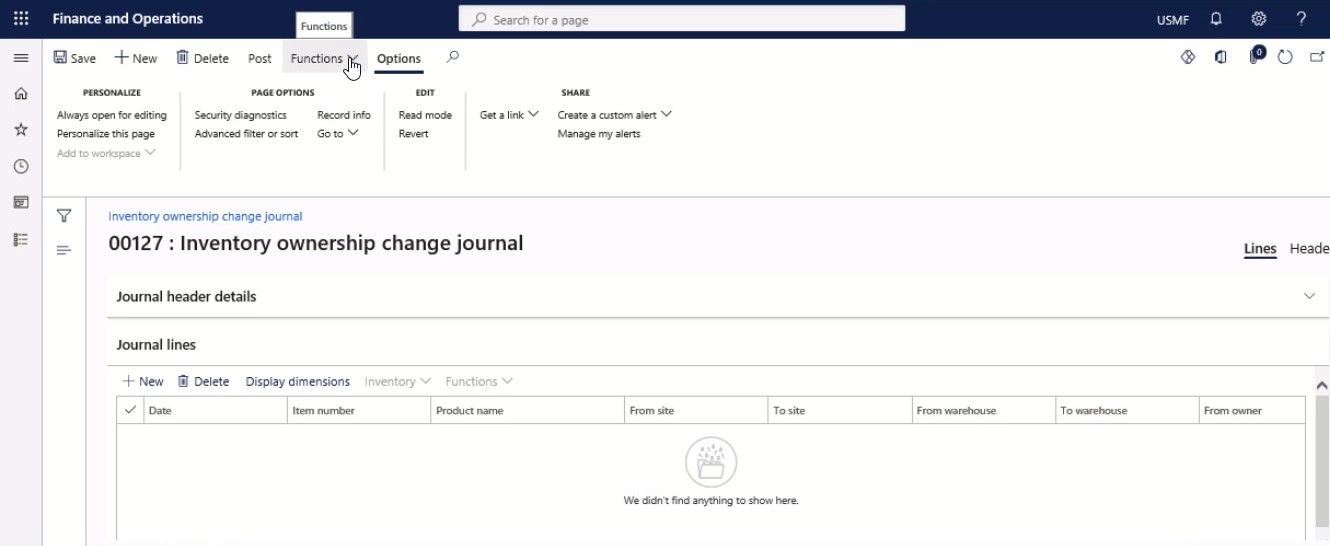

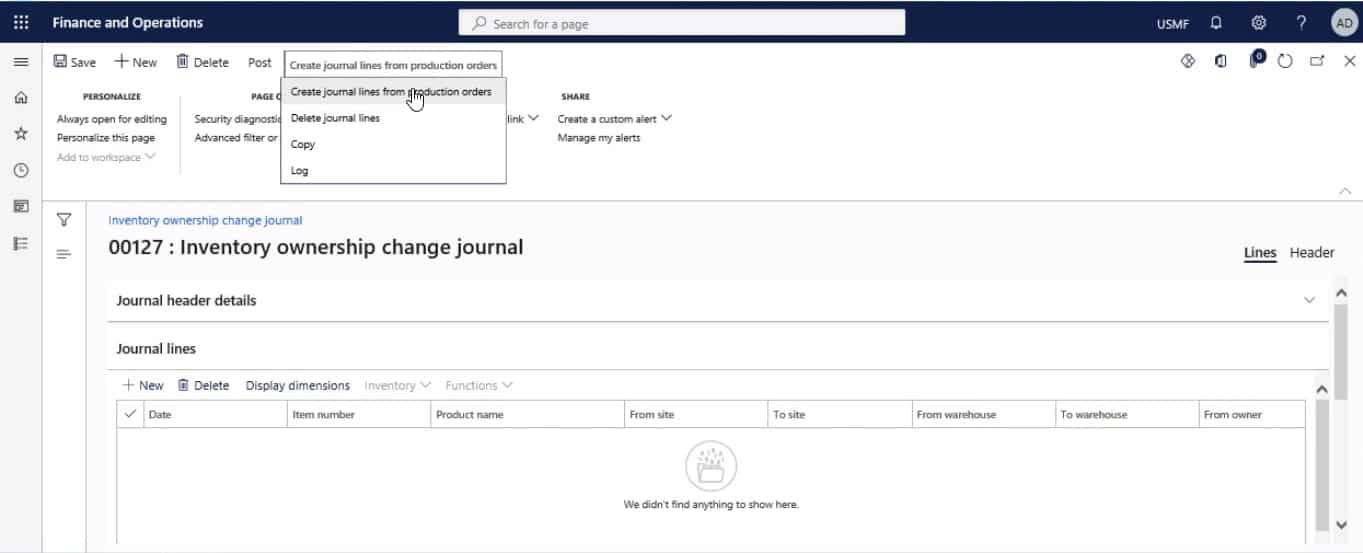

Click Functions.

Step 6

Now Click Create journal lines from production orders.

Step 7

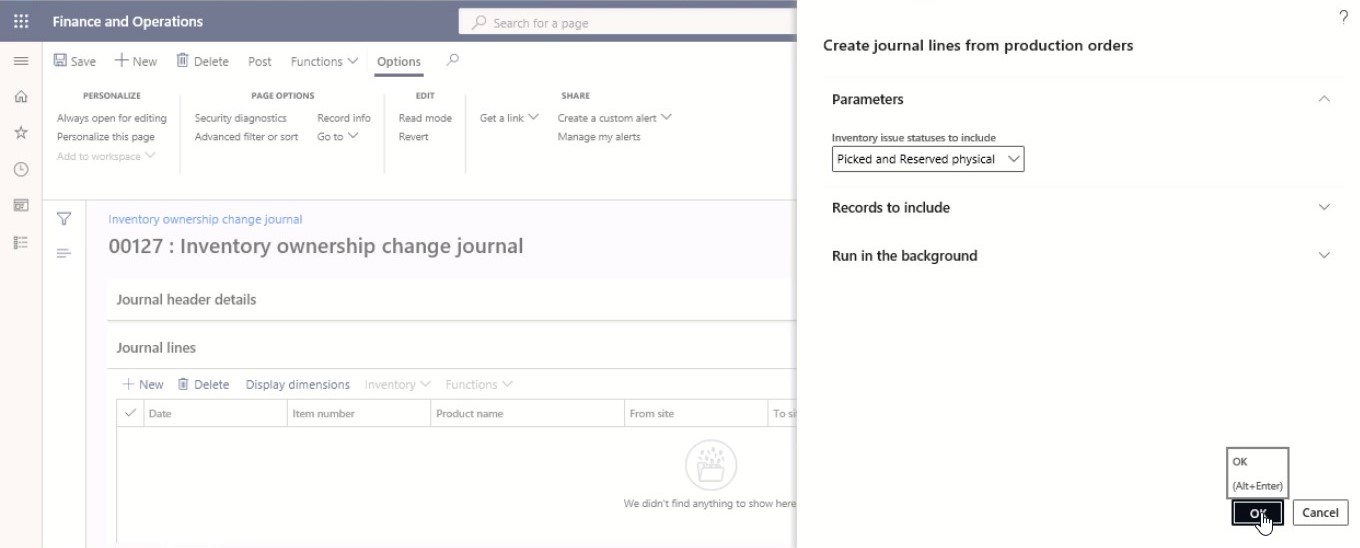

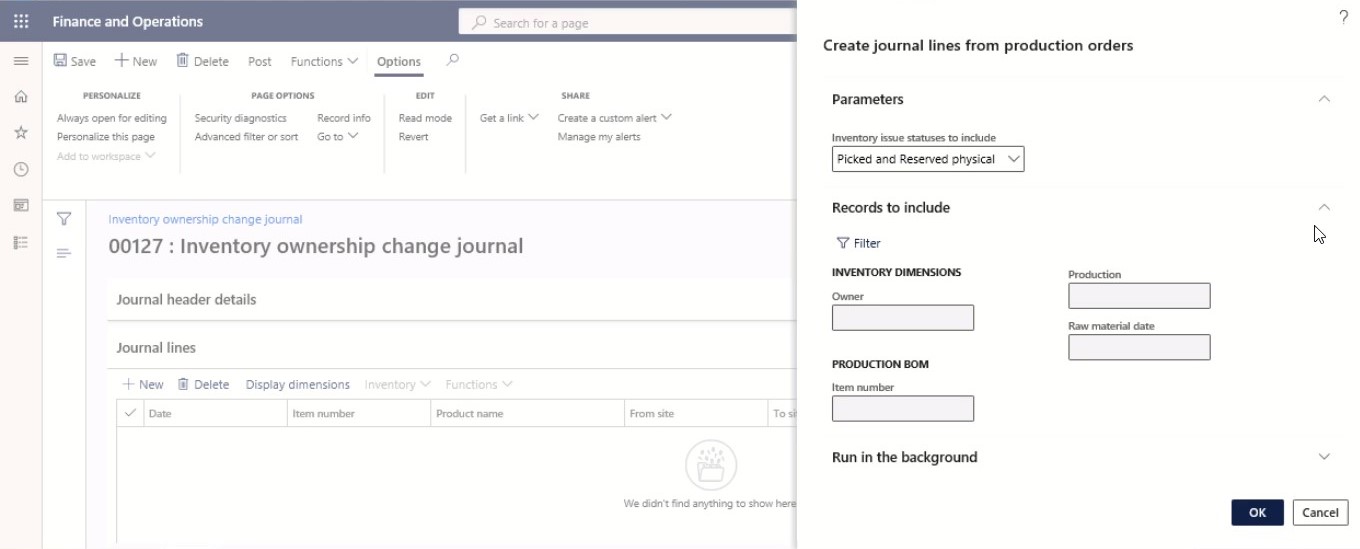

In the Inventory issue statuses to include field, select an option.

Step 8

Expand the Records to include sections if you want to apply additional filtering. Click Ok.

Step 9

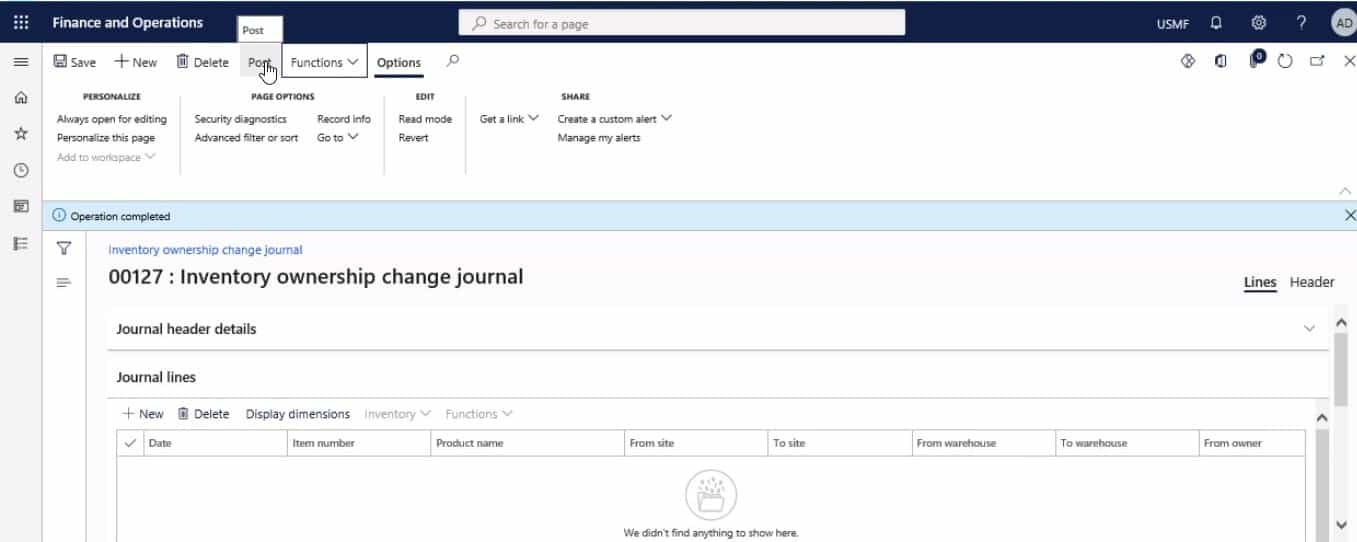

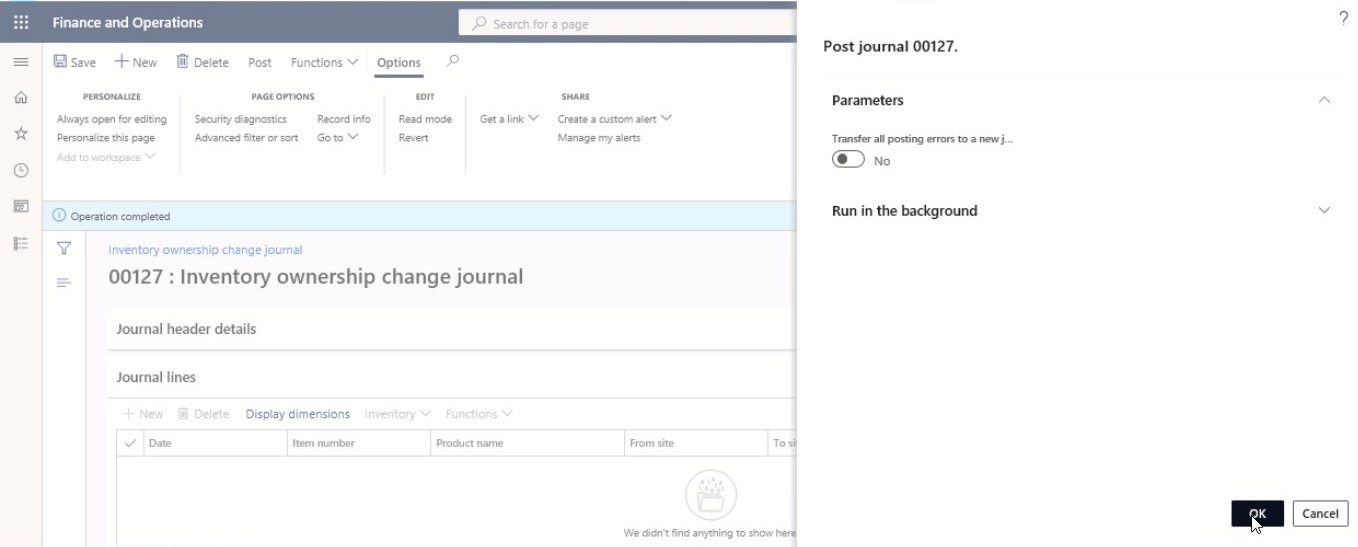

Click Post.

Step 10

Now Click OK.

Step 11

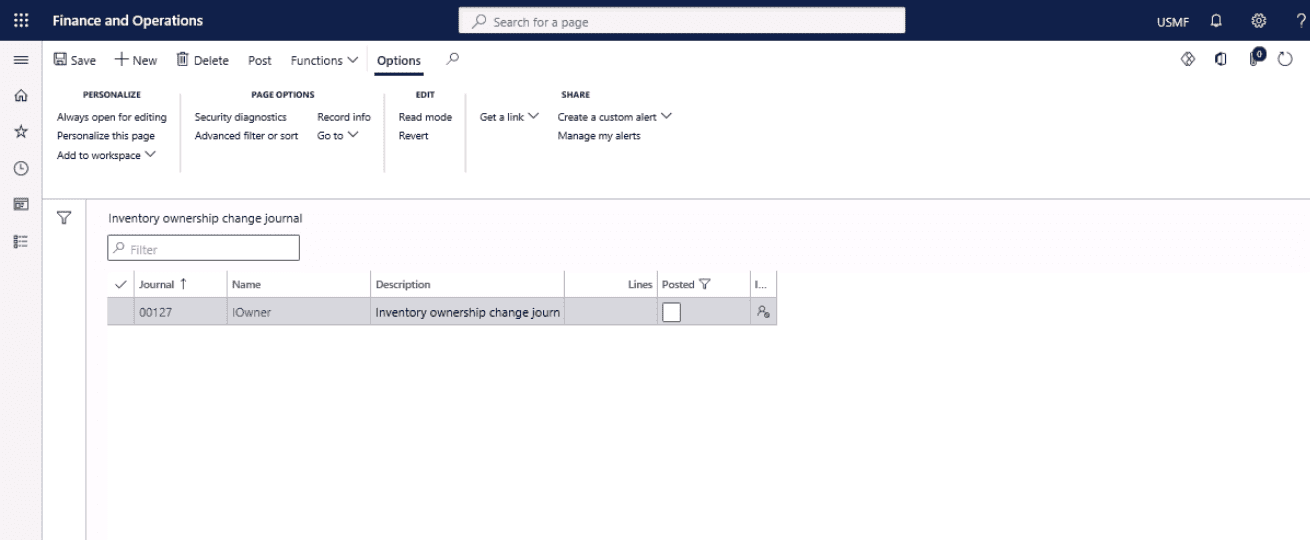

Close the page.

SUMMARY

Following the above steps, you will change the ownership of consignment inventory based on production demand.

What are the Best Practices for Consignment Inventory Management?

While consignment inventory has a role in the company, as discussed before, it adds another degree of complexity and risk. Regrettably, some retailers use it to lower their inventory carrying expenses by offloading risk to the provider. Due to the increased complexity of inventory management and accounting, the net cost savings are sometimes far less than projected.

To be successful, a consignment inventory agreement must benefit both parties and use technology to avoid extra expenses and risks.

Contracts for the Sale of Inventory on Consignment

A firm contract is critical to the success of a consignment deal. Both parties must comprehend the rules, including the payment schedule, any time constraints, shipping and return obligations, and who is responsible for product damage or loss.

The agreement must indicate how to tally and manage the inventory. This may need regular inventory updates, depending on the ownership structure. Deposits and commission requirements must also be specified. Naturally, the sellers must commit to taking reasonable steps to sell or utilize the consignment merchandise promptly.

Technology for Consignment Inventory

Managing consignment inventory often needs a precise tracking and invoicing system because payment or change of ownership occurs independently of the transportation procedure. Unless in a small specialist retail setting such as a gift shop or craft store, a spreadsheet or paper-based system will be unable to keep up. It’s critical to employ a system that manages inconsistencies between consignor and consignee to ensure inventory accuracy. A sophisticated system would manage inventories at numerous locations and offer statistics such as sell-through rates. The objective is for all parties engaged in the partnership to have complete insight into the stock.

Collaboration

Consignors and consignees should collaborate on marketing, promotion, and sales activities to develop and satisfy the demand for the items. When inventory turnover improves, everyone benefits.

Channels of Distribution

Most vendors should use several sales channels in addition to consignment. It is now simpler than ever to enter the world of e-commerce, and classic inventory solutions are also desired and often accessible. In addition, selling via several channels mitigates the seller’s risk and expands the seller’s earning potential.

| Sr. | Manufacturing KPIs | ||

| KPI | Definition | Formula | |

|

1. |

Asset Turnover | The term “asset turnover” refers to the amount of money earned by sales or revenues. It quantifies a manufacturer’s efficiency in generating income via the usage of equipment and other assets. Businesses that have a high turnover ratio are more efficient than those that have a low turnover ratio. | Asset Turnover = Net Sales / Average Total Assets |

|

2. |

Asset Utilization | The term “Asset Utilization” refers to the total income generated by each dollar of assets possessed. It determines the efficiency with which you are using your installed capacity. | Asset Utilization = (Actual Output / Maximum Capacity) *100 |

|

3. |

Availability | Availability is the difference between actual production time and anticipated production time. It is comparable to overall availability, except that it is calculated using scheduled production time rather than total calendar time. | Availability = Uptime / (Uptime + Downtime) |

|

4. |

Capacity Utilization | The rate at which prospective production levels are fulfilled or utilized is referred to as capacity Utilization. It simply keeps track of how much of a manufacturer’s production capacity is being used at any given point in time. | Capacity Utilization = (Actual output/Maximum possible output) *100 |

SUMMARY

Consignment is often thought of as a technique to reduce carrying costs by transferring risk to the supplier. Consignment is used by some businesses to reduce inventory carrying costs, but it adds another layer of complexity and risk. A consignment inventory agreement must benefit both parties and use technology to eliminate unnecessary expenses and dangers.

Final Thoughts

Both suppliers (consignors) and retailers may gain from a consignment inventory agreement (consignees). Suppliers may increase brand recognition by consigning goods and expanding into new markets. Retailers can diversify their product offerings without taking on excessive inventory risk.

Naturally, a good consignment arrangement is contingent upon a strong consignment inventory agreement. Each contract should specify who is responsible for missing or damaged products, how long things are held in inventory, who pays for transportation, and other pertinent information.

Regardless of how much faith you have in your supplier or how evident an aspect of the relationship is, be sure that everything is included in a formal business contract.

SUMMARY

Consignees and retailers benefit from a strong consignment inventory agreement. Consignees can increase brand recognition and expand into new markets. Retailers can diversify their product offerings without taking on excessive inventory risk.

At Instructor Brandon | Dynatuners, we always seek innovative methods to improve your competitiveness and suit your Microsoft Dynamics 365 requirements. Our offerings are founded on defined procedures, industry experience, and product understanding. If you’re interested to consult with our specialists on how consignment inventory can help you streamline your operations, then don’t hesitate to Contact Us.

[sc_fs_multi_faq headline-0=”h2″ question-0=”What is the definition of a consignment inventory?” answer-0=”With consignment inventory, the manufacturer keeps ownership of the goods until it is sold to a customer or consumed by a company. The shop or user is not charged until the goods are sold. The consignment model distributes the burden of inventory management from the merchant to the manufacturer. ” image-0=”” headline-1=”h2″ question-1=”What are some of the advantages of consignment? ” answer-1=”It enables a seller or maker to put items at wholesale and retail stores, thereby increasing exposure of goods to the purchasing market. It may give an incentive for wholesalers and retailers to maintain inventory levels, since their money is not connected to inventory. ” image-1=”” headline-2=”h2″ question-2=”How do you maintain inventory on consignment? ” answer-2=”A computer spreadsheet is one of the simplest methods to keep track of your consignment inventory. You may create a separate spreadsheet for each store and then detail each item on its own row. ” image-2=”” count=”3″ html=”true” css_class=””]

2264

2264